North Sea Giant, one of the world’s largest and most advanced subsea construction vessels (OSV), has installed an innovative cost-saving solution.

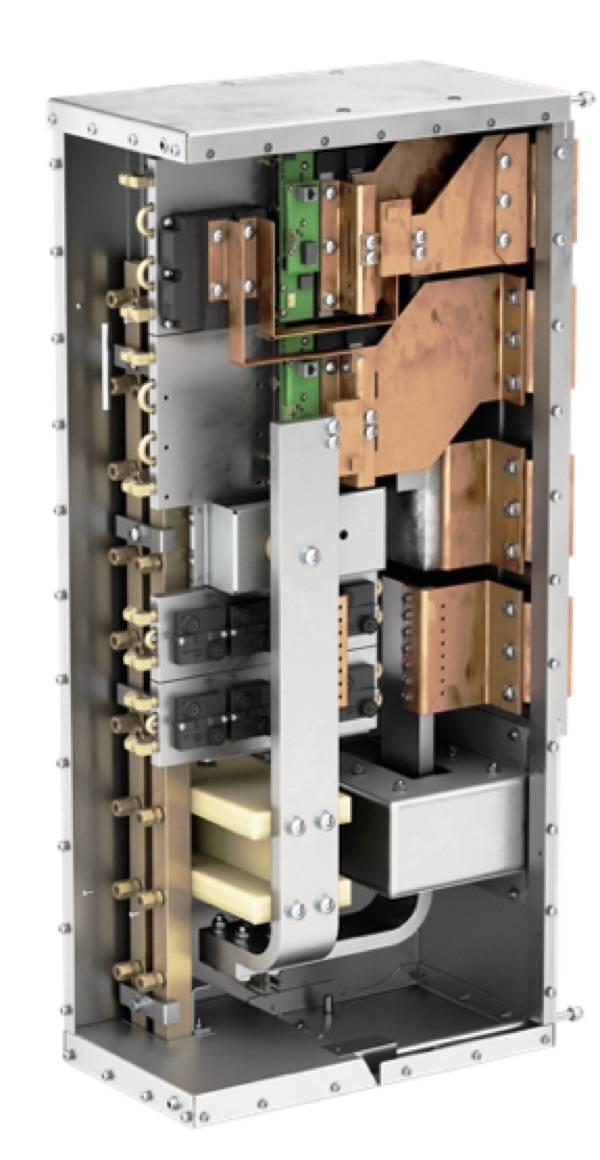

This system, based on a unique Electronic Bus Link (EBL) from Yaskawa Environmental Energy / The Switch, will enable the 18,151 GWT vessel to change between its diesel engines, running just one of its diesel engines during many operations, when necessary, rather than the standard three it used at all times in the past.

First order for fault-isolating innovation

Yaskawa Environmental Energy / The Switch is a specialist in the development and supply of advanced drive train solutions. Since acquiring Wärtsilä Drives in November 2016 to help build its marine market share, the firm has gone on to secure many orders for its established permanent magnet (PM) shaft generators, DC-Hub technology and electric propulsion solutions. The North Sea Giant EBL order is the company’s first for this breakthrough product.

“For owners that want to optimize efficiency, operational uptime, cost control and reduce their environmental footprint, EBL is the perfect solution,” says Asbjørn Halsebakke, General Manager, Yaskawa Environmental Energy / The Switch Norway.

Microsecond response, safe operation

“It works to connect the vessel’s DC-Hubs and diesel engines and ensure efficient ongoing operations, even if a critical fault occurs. It does this by splitting the on-board grids in a matter of microseconds, isolating faults and protecting the complete operational system. This offers significant savings on maintenance costs. Also, by rapidly connecting and disconnecting energy sources from one another, including batteries and engines, they can be optimized for efficiency. This eliminates the need for the operator to run three different units during all operations, saving on long-term fuel costs and reducing emissions.”

“This is the first vessel in the world approved to run a DP3 class dynamic positioning system with one engine and batteries – a global game changer,” states Halsebakke.

The Switch technology, supplied as part of a broader Wärtsilä solution, was installed in Haugesund, Norway, after a program of rigorous testing supervised by DNV GL.

Saving money and boosting uptime

“We’re not just focused on providing the best technology, but also the best service,” Halsebakke continues. “We are committed to ensuring that all our customers – both end users and system suppliers − get the solution they want, when they want it. North Sea Giant can now look forward to real cost savings, emissions reduction and reduced operational downtime with the EBL.”