Kvaerner and Aker Solutions on Thursday cut the first steel plate for the second phase of the Johan Sverdrup offshore field development, kicking off Norway’s largest industrial project in three decades.

The two Norwegian engineering firms have been working in a 50/50 joint venture under a NOK 3.4 billion contract to support operator Equinor’s Johan Sverdrup Riser Platform modification project since May 2018. The scope of work includes engineering, procurement, construction and installation (EPCI) of a utility module, as well as modifications of the field center and integration of a second processing platform.

The 5,000-metric-ton utility module will be built at Kvaerner's yard at Stord, with prefabrication performed by various subcontractors in Poland. Aker Solutions' yard in Egersund will perform the prefabrication for the offshore integration.

The first steel plate cut Thursday will be utilized at a bridge support module which will be positioned where a new bridge is connected to the existing riser platform at the Johan Sverdrup development on the Utsira Height in the North Sea, approximately 160 kilometers west of Stavanger.

The sections of the Johan Sverdrup field that are built in the first phase will start production in 2019, while the sections in phase two are slated for production startup in 2022. Phase one includes four platform topsides on steel jackets, where Kvaerner is the supplier of one topside and three steel jacket substructures. Phase two includes a new platform topside on a steel substructure, including the new module that Kvaerner will deliver in cooperation with Aker Solutions. Kvaerner will also supply the steel jacket that will carry the new phase two processing platform topside.

Construction underway at the Johan Sverdrup field in October 2018 (Photo: Equinor)

Construction underway at the Johan Sverdrup field in October 2018 (Photo: Equinor)

The Johan Sverdrup development, which will be one of Norway’s biggest sources of incomes in the coming decades, relies on heavy participation across the domestic supply chain. According to Equinor, contracts worth more than NOK 60 billion have been awarded in connection with the phase one development, with 70 percent of the total number of contracts awarded to Norwegian suppliers.

As was the case for phase one, “phase two of Johan Sverdrup is realized through solid cooperation between Equinor and the Norwegian supplier industry to reduce field development costs significantly,” Kvaerner CEO Karl-Petter Løken explained. “This means even higher value creation for Norway, both through industrial development and employment throughout the country, and it includes significant income from future production of oil and gas.”

Kvaerner said peak manning on the project for its part will be around 550 people, plus a further 300 at Aker Solutions. Including subcontractors and service companies, the contract is expected to create ripple effects for around 2,000 jobs.

“Johan Sverdrup is not only Kvaerner’s most important project in recent years, it is also Norway’s biggest industry project in recent times,” Løken said.

Equinor is the operator for the development, which spans over three licenses. Other partners include Lundin Norway, Petoro, Aker BP and Total.

One of the five largest oil fields on the Norwegian continental shelf, Johan Sverdrup is estimated to hold 2.2 billion to 3.2 billion barrels of oil equivalents. It is expected to produce up to 660,000 barrels of oil equivalents a day when fully developed in 2022, equal to about a quarter of current domestic output.

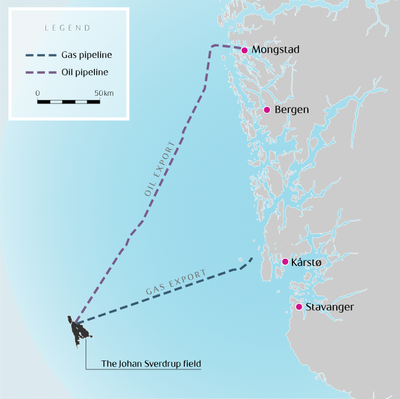

Oil from the field will be piped to the Mongstad terminal in Hordaland, and gas will be transported via Statpipe to the Kårstø processing plant in North Rogaland. (Image: Equinor)

Oil from the field will be piped to the Mongstad terminal in Hordaland, and gas will be transported via Statpipe to the Kårstø processing plant in North Rogaland. (Image: Equinor)

Aker Solutions provided feasibility and concept studies for the Johan Sverdrup discovery in 2012-2013, supporting the partnership in developing a development concept. In late 2013, the company won a portfolio framework agreement from Equinor to provide engineering services, procurement and management assistance (EPMA) for the first phase of the development. The front-end engineering design (FEED) was executed in 2014, engaging one of the largest FEED teams ever assembled by the company to detail out the four platform field center concept.

In 2018, Aker Solutions completed the FEED for phase two of the development, including the module and work to integrate this with the riser platform. This work was secured in 2017 as part of a 10-year framework engineering agreement for Johan Sverdrup that was awarded to Aker Solutions in 2013.