While the offshore industry has focused on cutting costs, Weatherford – known primarily as a land-based completions company – has invested heavily in building an offshore completions line.

Mark Hopmann, Weatherford’s Completions president, says the service company’s move to provide solutions for the offshore industry ultimately benefits operators looking to safely trim opex costs.

The primary ways to cut opex costs, he notes, are through reducing the costs of products and services, and through decreasing the amount of time it takes to drill and complete each well. Weatherford, he says, has targeted decreasing time by creating technologies that can be installed more quickly.

“We’re focusing on the problem, not making the [existing] kit or equipment we have fit the application,” he says. “We went out and attacked the problem with a clean sheet approach to bring the technologies to market.”

The last five years have seen the service company develop some key time-saving completions technologies for the offshore industry, Hopmann says.

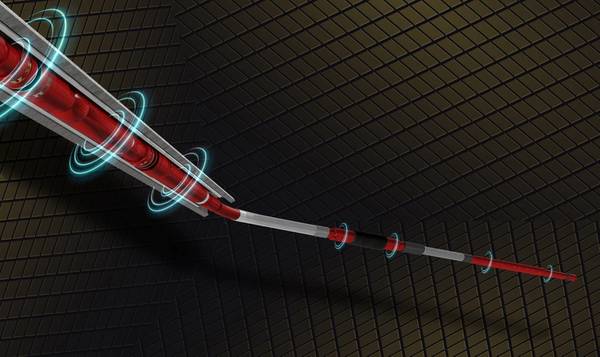

One of the company’s biggest contributions in that vein, he says, is TR1P, a single-trip completion system establishes that makes it possible to install the upper and lower completions in just one trip. Traditionally, the upper completion is set in one trip and the lower completion in a second trip, due to well control issues, and each trip requires a certain amount of rig time.

TR1P makes it possible to perform multiple operations in less time and with fewer equipment and personnel, according to Weatherford. A key to the TR1P completion system, Hopmann says, is the use of RFID valves to maintain well control. The service company deployed the TR1P technology for a well offshore Nigeria, setting both the upper and lower completions in one run.

“The operator said we broke the run time record by four days over what they’d been able to achieve in that field in offset wells,” Hopmann says.

Mark Hopmann, Weatherford’s Completions president (Photo: Weatherford)

Mark Hopmann, Weatherford’s Completions president (Photo: Weatherford)