Anyone who works in business knows the importance of following processes to achieve successful outcomes. When it comes to the oil and gas industry, one misstep, change or delay can throw the entire process off, rendering resources useless and costing a company thousands, if not millions of dollars. An example that is seen quite often in offshore drilling is equipment damage. If materials are delivered after receiving damaging impacts, and no one knows about it, the results are wasted travel and labor expenses, along with potential downtime.

This has real-world business impacts, and equipment problems occur every day for companies across the world. For example, an offshore drilling company needed to reduce downtime caused by damaged motors, pumps and gas injection equipment because of the impact it had on their bottom line. The transportation process from the company’s operations base to offshore platforms was lengthy, providing multiple opportunities for damages to occur. However, since the process wasn’t transparent, there was no way to allocate cause or blame once damages did occur, leaving the company with unusable equipment and no way to know how or where it happened.

Before transportation, the first step in the process was moving equipment from the operations base to a loading dock 115 miles away in Rio de Janeiro, Brazil. From there, the equipment, encased in thick steel containers, was loaded onto a ship and transported 120 miles offshore where the containers were moved to an oil platform. A single rotation of this supply chain took anywhere from five to seven days, including waiting periods, a 7-hour drive to a shipping yard and a 12-hour voyage out to the platform.

If damages occurred during transportation, they weren’t realized until after the five to seven day process had already taken place and workers were more than 100 miles offshore trying and failing to use the equipment to test wells. This resulted in additional costs for new equipment, extended labor, scheduling issues and long periods of downtime.

The culmination of all these setbacks was an estimated loss of $140,000 per day until new, working equipment arrived. With an average process of five to seven days, that amounted to more than $700,000 each time damage occurred.

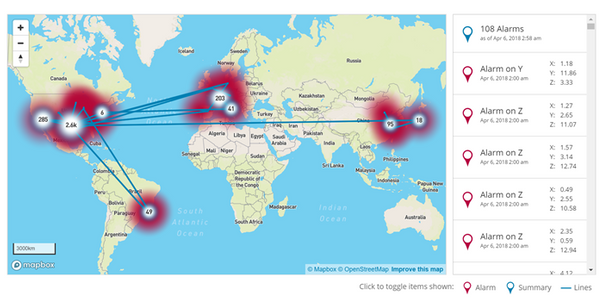

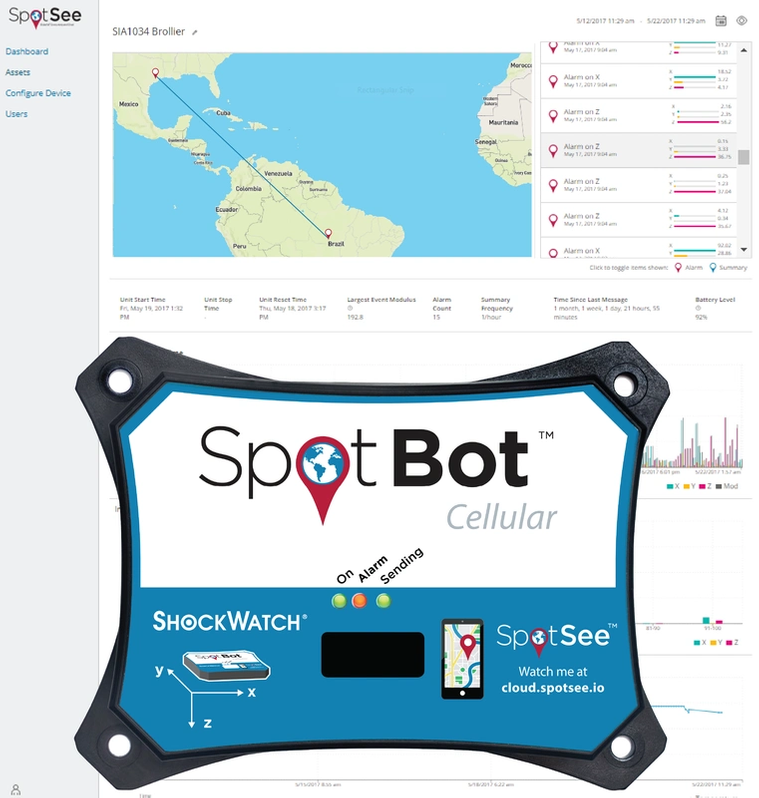

This is a major loss to any company, but it can be avoided. To solve these issues, the offshore drilling company implemented multiple impact-monitoring devices, such as SpotBot Cellular, which provide real-time 3-axis impact alerts and locations through the SpotSee Cloud. This gave the offshore drilling company the ability to see when, where and why equipment was breaking. After a trial period, the data showed equipment was being damaged three different times: when a container was moved horizontally and banged against another, when the container was loaded onto the ship with a crane and when the container was initially loaded at the operations base.

Ultimately, the company was able to see where in the supply-chain process the damage was occurring, what G-force level the damage occurred and enabled them to stop any damaged equipment from progressing through the process, preventing further delays or loss of resources.

With this monitoring method, not only can companies track impacts for damage, but they can also monitor vibration for potential equipment failure during operation. The use of real-time monitoring devices is vital for oil and gas companies moving forward, and the ability to decrease downtime and increase efficiency cannot be undervalued.

(Image: SpotSee)

(Image: SpotSee)

The author

Roberto Pinheiro joined SpotSee in 2017 tasked with leading growth and expansion of the company in his role as General Manager for Central and South America. During his career, he has held several managerial roles in sales, business and strategy, and is experienced in process control, instrumentation, pneumatic components and technology.