Seabed deployed remotely operated underwater vehicles (ROV) are already here. Since early last year, IKM Subsea has been operating its Merlin UCV R-ROV (resident ROV) from a cage placed beneath Norwegian operator Equinor’s Snorre B production facility offshore Norway. It’s powered by and connected to, for communications and control, the Snorre B facility and deployed for three-months at a time before being retrieved for maintenance. By operating the ROV from the cage on the seafloor, launch and recovery operations are no longer reliant on the weather and the ROV can be on site faster when it’s needed. Furthermore, it’s able to be operated either by ROV operators on the facility or from an onshore control room near Stavanger, via fiber optic cable.

In April, Oceaneering’s E-ROV (E for empowered) will take a different tack, working off vessels in Equinor’s inspection, maintenance and repair (IMR) fleet. Using a concept demonstrated by Oceaneering using its e-Novus ROV last year, the battery-powered E-ROV will go out with the IMR vessels, be deployed at a site where it’s required, together with a 600-meter tether management system and fiber optic cable to a surface communications gateway buoy. This will enable communication and control via 4G LTE from an onshore control room, leaving the IMR vessel free to do other work.

Not yet commercialized is an idea which would take these concepts a step further – ROV deployment from unmanned surface vessels (USV). Total and TechnipFMC have been exploring this idea for light subsea IMR activities working with France’s ECA Group. ECA Group says that a successful demonstration of the ability to carry out an inspection task using its Hytec H300V observation class ROV deployed from a USV Inspector, using a wireless communication link (surface communications gateway), was demonstrated earlier this year. During the operation, an onshore operator conducted repetitive tasks on a simulated subsea asset, using the ROV, deployed from the Inspector 90 USV.

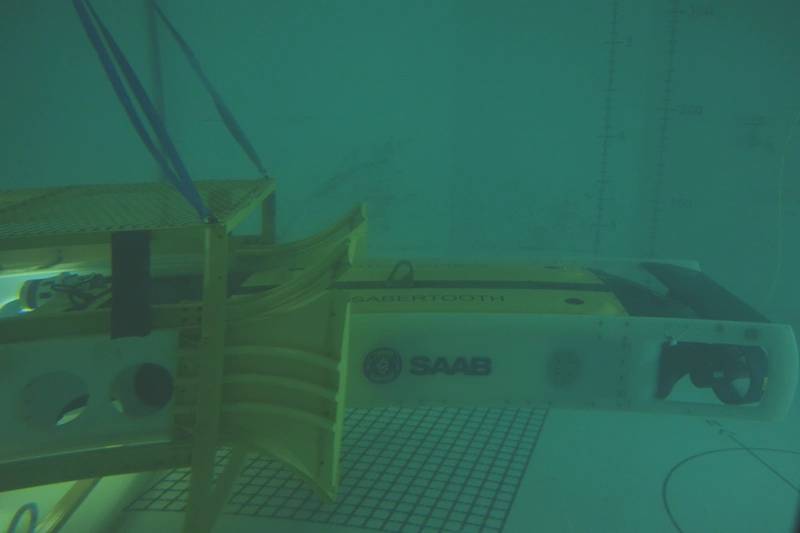

Saab Seaeye’s Sabretooth has been fitted with a Blue Logic connector and proven inductive data and charging (Photo: Saab Seaeye)

Saab Seaeye’s Sabretooth has been fitted with a Blue Logic connector and proven inductive data and charging (Photo: Saab Seaeye)

Cutting the cord

All of these systems so far rely on tethers for power and communications/control or, where the vehicle is battery powered, communications/control. For those wanting to shed the tether, autonomous underwater vehicles (AUVs) are the guiding light.

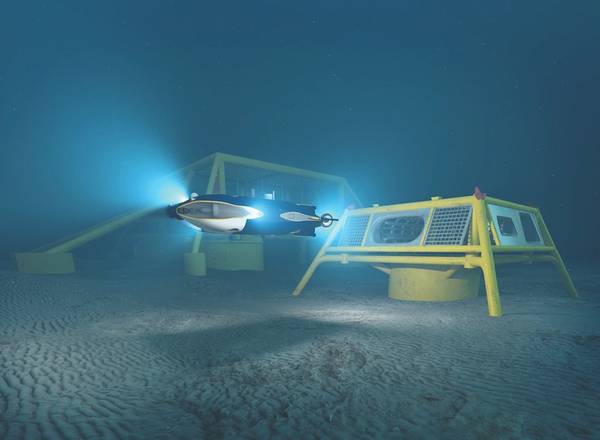

Earlier this year, Saab Seaeye says it achieved a world first by showing that underwater electric vehicles can dock at remote deepwater sub-resident resident docking stations for data transfer, assignment instructions and battery charging.

Its 3,000-meter-rated Sabertooth can already work remotely on preprogrammed or man-controlled missions, including IMR, research tasks and environmental monitoring. Now, fitted with a 2-kilowatt/80-megabits-per-second Blue Logic inductive charger and data transfer device, the hybrid AUV/ROV was able to dock, charge and download data in a trial in Saab Seaeye’s test tank facilities. This means it can now dock, charge and up or download data at any docking station – including a standard design proposed by Equinor – where there’s a respective Blue Logic connection, as well as change out tooling, says Jan Siesjö, chief engineer at Saab Seaeye.

“We have had the docking station and autonomous docking based on transponders and using BlueComm for quite a while, but power and data transfer hasn’t been done before. This is the final missing piece for complete system that can do these resident jobs,” Siesjö says.

Separately, Saab Seaeye is working with ocean energy technology firm Ocean Power Technologies (OPT), with which it has an agreement to jointly develop and market solutions for AUV and ROV charging and communications systems, using OPT’s PB3 PowerBuoy as a power supply and surface data gateway. For Siesjö, a key enabler is surface communications. “There is 4G over most of the North Sea,” he says. “With that, all of a sudden you can have a docking station with a communications buoy or a USV supporting an AUV with communication. All of the pieces are there.”

Saab Seaeye’s Sabretooth it in its test tank (Photo: Saab Seaeye)

Saab Seaeye’s Sabretooth it in its test tank (Photo: Saab Seaeye)

Demonstrating docking

Modus Seabed Intervention will take delivery of its second, deepwater-rated Sabertooth hybrid AUV (HAUV) this summer. In 2017, the company performed demonstrations and trials and its existing HAUV was ready for commercial operations in 2018. In one of the 2017 trial projects, the HAUV was launched from a quayside at a lake close to Saab’s Facility in Sweden to perform a “mow the lawn” style pre-programmed survey collecting multibeam echosounder (MBES), side scan sonar (SSS) and sub-bottom profiler (SBP) data over about 15 kilometers, with no external aiding from a support vessel – just the vehicle’s differential Global Positioning System (DGPS), inertial navigation system (INS) and doppler velocity log (DVL). “Having gone out and repeated the survey, it saw very little drift,” says Nigel Ward, the firm’s chief commercial officer. The vehicle was also successfully trialed multiple times, autonomously docking into its subsea garage.

In early 2018, a trial as part of an Innovate UK funded project for wind farm resident inspection performed out of the ORE Catapult facility in Blyth, England, involved indirect power coupling and data transfer using a Blue Logic inductive connector. In the final phase of this demonstrator project, later this year, in between its commercial commitments, Modus will trial a resident HAUV concept at an offshore wind farm in the UK.

Modus Seabed Intervention’s H-AUV in the water (Photo: Modus Seabed Intervention)

Modus Seabed Intervention’s H-AUV in the water (Photo: Modus Seabed Intervention)

Last year, Modus deployed a HAUV offshore northwest Australia to perform more than 200 kilometers of pipeline integrity survey, producing images and point cloud data, of both the pipeline and passing marine life using a Cathx laser and HD camera spread alongside a multibeam echosounder. “The survey time was half of what it would have taken using a traditional ROV to perform the survey and it could have been faster,” says Modus CCO Nigel Ward. “Such a survey is possible without a tether, but it was performed with a tether on this occasion so that real time data could be collected.” Modus has also been trialing Force Technology’s FIGS system, which can do noncontact cathodic protection surveys at 4 knots, alongside while doing general visual inspection (GVI) survey.

Modus Seabed Intervention has been trialing docking and resident vehicle operations offshore the UK. (Photo: Modus Seabed Intervention)

Modus Seabed Intervention has been trialing docking and resident vehicle operations offshore the UK. (Photo: Modus Seabed Intervention)

During a pipeline inspection, Modus Seabed Intervention’s H-AUV captured striking images of sharks over the pipeline. (Photo: Modus Seabed Intervention)

During a pipeline inspection, Modus Seabed Intervention’s H-AUV captured striking images of sharks over the pipeline. (Photo: Modus Seabed Intervention)

Subsea 7’s 3,000-meter-rated autonomous inspection vehicle (AIV) is, like the Sabertooth, able to hover, (for close up inspection). It’s an infield inspection vehicle with 24-hour endurance, says Alan Gray, from Subsea 7 company i-Tech 7. The 1.7-meter-long, 1.3-meter-wide, 0.8-meter-high vehicle (750 kilograms in air), with lithium ion batteries can do a 40 kilometers round trip, he told Subsea Expo in Aberdeen earlier this year, and performed 36 inspections during a single 18-hour period last year. It’s done four offshore trials, including docking and has reached TRL5 (technology readiness level), he said. The AIV, which can communicate via acoustic, radio or 4G networks, could be used during simultaneous operations operating from a garage, to free up the IMR vessel for other work, says Gray. But, it’s also been built with autonomy in mind. It uses a map combined with sonar to navigate and has an advanced planning system, with an intuitive map on which you can point and click to plan missions, says Gray. Using through-water communications could then bring the human in the loop for complex tasks, although there’s still some work to do here, he says.

Next into the water will be Oceaneering’s Freedom vehicle. Oceaneering says that the 3.3-meter-long completely new design vehicle will be able to perform inspection, advanced survey and light intervention work, autonomously (out to 50 kilometers without a tether or 250 meters with a tether) or under remote control, using a modular design that means it can be configured for the mission it’s required for. This will comprise a common center section with ends that can be interchanged. Freedom has a carbon fiber outer body, providing strength and encasing its buoyancy, instead of the traditional skeleton type structure of ROVs.

A prototype is being built in the US, ready to go on show at the Offshore Technology Conference in Houston, says Arve Iversen, ROV Operations Manager Special Projects at Oceaneering. After that, it will be shipped to Norway for testing in Trondheim fjord. Meanwhile a test vehicle has been built in Norway so that the control system and autonomy software, being developed with help from the Norwegian University of Science and Technology (NTNU), can be tested.

“This year we are focusing on control, obstacle avoidance, object recognition, and things like that. Docking will come and we will be able to dock with the docking station that Equinor has developed, and we will be using that for docking testing in Trondheim,” says Iversen. Equinor’s docking station is a standardized solution, also using inductive connectors, which it wants all subsea vehicles that it might want to use to be able to dock in to. “We think a standardized docking station is the way forward,” says Iversen. “The business case is difficult if everyone is going to have their own.” Iversen says with just 17 docking stations, the entire Norwegian continental shelf could be covered by Freedom, due to its range.

There are more hybrid AUV projects in the pipeline, including FlatFish, a resident autonomous vehicle which Shell licensed Saipem to develop last year and is expected to be qualified for commercial application by 2020. Saipem also has its Hydrone family of vehicles. Meanwhile, back in Trondheim, technology spin-out Eelume is set to test its latest 20-centimeter-diameter snake robot, EELY500, which has eight thrusters for propulsion and stability. It’s already been tested at 370 meters in a fjord near Trondheim. The next step is deployment from an Equinor designed docking station at the operator’s Åsgard field, initially on a tether, where it can recharge its batteries and pick up tools.

Kawasaki Heavy Industries has launched a UK subsidiary, Kawasaki Subsea (UK), based in Aberdeen, that is focusing its efforts on developing AUVs for oil and gas pipeline inspection and later maintenance. A prototype of its vehicle, called SPICE (submarine pipeline inspection with close eyes), was tested at the now closed Underwater Center in Fort William in 2017 and is due to be commercially launched in 2020, with control software developed in cooperation with the UK’s Heriot-Watt University. Testing included automated docking of the AUV to a prototype charging station, contactless charging and large-capacity optical communication operations.