Customer pressure for 20,000 psi-capable equipment has persisted for over a decade, yet no industry standards have been firmed up. This hasn’t stopped orders for such equipment, although some were later cancelled.

Baker Hughes, a GE company, has a prototype 20K subsea blowout preventer (BOP) and associated equipment in its lab in Houston. The 20K BOP has been fully tested and fully qualified to the latest draft of API 16A 4th Edition PR2 and Annex H, the Specification for Drill-through Equipment, said Bob Judge, director of drilling products for BHGE.

That said, noted Viral Shah, systems engineering manager at BHGE, the existing 16A specifications don’t actually address equipment exceeding 15K psi, although a draft outlining 15K+ psi specifications, called Annex H, is in progress.

“We have exceeded the draft requirements set forth in Annex H,” Shah said. “There are a lot of moving pieces as soon as you go above 15,000 psi. Getting to the finish line was not easy, but we are there now.”

When BHGE started this effort, Judge says, the API 16A 4th Edition PR2 designation did not exist.

“That is new,” Judge said. “As the regulations change, we have to acknowledge that and continue the development.”

One of the biggest changes from existing to proposed regulations is a standard on analysis, such as for material characterization and fatigue analysis, Shah noted. Not only did standards not exist when the initial order was placed for a 20K subsea BOP, but different market conditions prevailed, he added.

“In the absence of a standard, the industry has had to do its best to understand conditions unique to 20K that are different than 15K that we might encounter,” Judge said. There are infinite possibilities, he said, which BHGE has distilled to a manageable number. “From a design and testing perspective, this is the most rigorous thing we as an industry have done.”

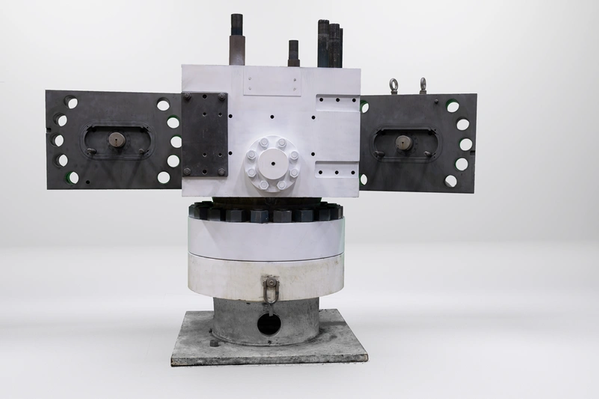

20K BOP Stack with six rams and two annular stacks. (Source: BHGE)

20K BOP Stack with six rams and two annular stacks. (Source: BHGE)

BHGE’s 20K BOP has an 18.75 inch bore diameter and is rated up to 350 degrees Fahrenheit. The rams have 2.55 million pounds of shearing force. The footprint for the entire stack is approximately 20 foot x 15 foot. Depending on the configuration, the stack is either about 49 feet or 56 feet tall and weighs about a million pounds.

“When we started on the 20K journey, we were looking at someone building a purpose-built drillship for 20,000 psi. Then the market changed. Customers wanted to know, ‘can we retrofit existing rigs for 20K?’” Shah said. “We have since then designed our 20K stack to match the footprint of the 15K BOP stack which allows our customers to retrofit existing rigs.”

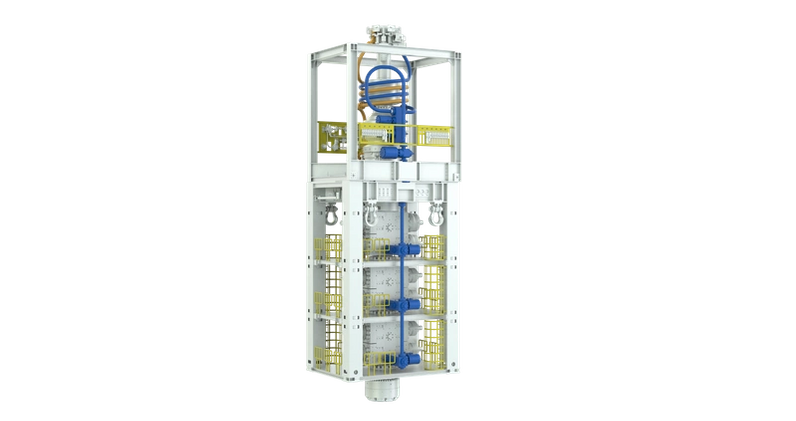

To date, BHGE has built the 20K BOP prototype and associated equipment, which it is keeping in a Houston lab for testing and development and qualifying the rams, Judge said. BHGE in 2017 began shipping API 16A qualified 20K subsea wellhead connectors for capping stacks.

BHGE is now running a Front End Engineering Design (FEED) study with an operator to design and validate 20K equipment to their specific requirements to allow the operator to deploy 20K equipment in Gulf of Mexico.

There have been operators thinking about 20K equipment, ranging beyond BOPs to wellheads, trees and other equipment.

“The market has identified a need and desire, but I don’t think the economics work out yet,” Judge said. “We’re in a watch and wait mode, and when the industry is ready, we’re ready.”

The 20K wellhead connector has been qualified and tested to API 16A 4th Ed and Annex H requirements. (Source: BHGE)

The 20K wellhead connector has been qualified and tested to API 16A 4th Ed and Annex H requirements. (Source: BHGE)