Halliburton leveraged technology from the mining industry to reveal subsurface structures in a way that improves geosteering, geomapping and geostopping in complex reservoirs.

The service company has introduced EarthStar 3D Inversion, a 3D reservoir mapping process that, when used in geosteering applications, can maximize contact with oil and gas zones while mapping the surrounding formation to identify bypassed oil, avoid drilling hazards and plan for future development.

Derick Zurcher, Halliburton’s strategic business manager for measurement-while-drilling (MWD)/logging-while-drilling (LWD), says the service company worked with mining software specialists Computational Geosciences, based in Vancouver, to “break down this large mathematical problem” of how to process the large number of measurements into a fully resolved 3D volume that could be useful in geosteering applications.

“They were looking at where the ore distribution is in the subsurface. We’re trying to do the same thing, where is the distribution of oil and gas?” Zurcher says.

Currently, reservoir data used for geosteering typically comes from seismic, which may not “see” features smaller than 150 feet, and while-drilling tools that take measurements near the wellbore. This leaves “a big gap” between the two, Zurcher says. “For the first time, we have a service which can resolve that intermediate scale.”

The 3D inversion capability uses Halliburton’s existing EarthStar ultra-deep resistivity service, an LWD technology that identifies reservoir and fluid boundaries up to 225 feet (68 meters) from the wellbore. EarthStar 3D Inversion reveals features such as faults, water zones or local structural variations such as injectities, which could alter the optimal landing trajectory of a well, according to Halliburton.

“The industry now has a solution to understand the hydrocarbon distribution in the reservoir that wasn’t there before,” Zurcher says.

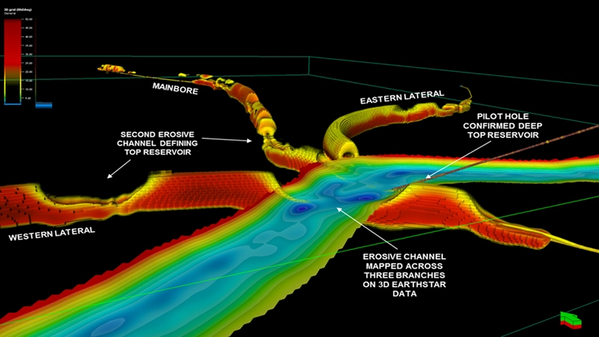

The new capability has been run in about a dozen wells offshore, including the North Sea and in the Americas. In one run for Aker BP offshore Norway in late 2018, the operator was aware of complex geology involving turbidite channels and wanted to be able to optimally land the wellbore in the reservoir.

1D inversion showed isolated sand bodies, Zurcher says, but 3D inversion “showed the true shape and extent of these channels and whether they’re connected, which was important for completion design and production.”

The service could be useful beyond real-time geosteering applications, he says, including use in mapping the water front in a reservoir.

“We believe this isn’t just a formation evaluation service. It goes beyond that,” he says, adding that it provides important input for the completion and production phases of reservoir development.