Construction on SBM Offshore's third Fast4Ward floating production, storage and offloading unit (FPSO) hull recently began at Chinese shipyard Shanghai Waigaoqiao Shipbuilding and Offshore (SWS), the Dutch FPSO provider revealed on Thursday.

SBM, which is building the hull on spec, said in its 2019 half year earnings report that it is "confident that this hull will be allocated to an identified opportunity."

SBM's Fast4Ward concept, launched in 2016, uses standardized specifications and modular components to lower costs and accelerate delivery times.

"The company’s Fast4Ward program brings scale combined with a reliable execution schedule and shorter cycle time to first oil. The program also enables the company to increase productivity and resource flexibility," said SBM CEO, Bruno Chabas.

"Fast4Ward brings additional resource flexibility and efficiency from repetition and standardization. This effect is visible not only in execution, but also in tendering and in onboarding new staff in the new ways of working," Chabas added.

The first of these standard, multipurpose floaters currently under construction is allocated to the FPSO Liza Unity and left the SWS drydock on June 8, 2019. Bound for the ExxonMobil-operated Stabroek block offshore Guyana, the FPSO will produce up to 220,000 barrels of oil per day, with associated gas treatment capacity of 400 million cubic feet per day and water injection capacity of 250,000 barrels per day. The FPSO will be spread moored in water depth of about 1,600 meters and will be able to store around 2 million barrels of crude oil.

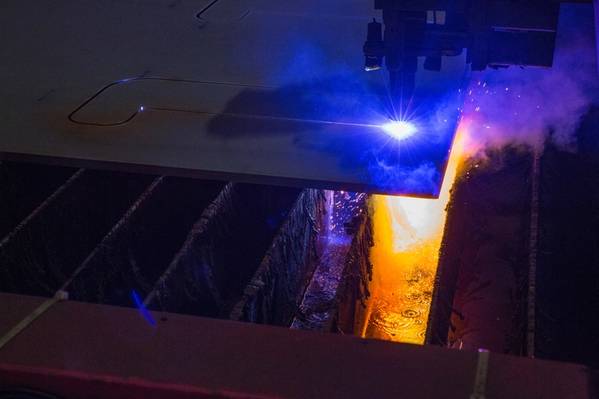

SBM said good progress is being made on the second hull, with first steel cut at the China Merchants Industry Holdings (CMIH) yard in July. The hull is allocated to the FPSO Mero 2 for the Petrobras-operated Libra block within the pre-salt Santos Basin offshore Brazil. The Mero 2 FPSO will have the capacity to process up to 180,000 barrels of oil per day (bpd), with water injection capacity of 250,000 barrels per day, associated gas treatment capacity of 12 million standard cubic meters per day and a minimum storage capacity of 1.4 million barrels of crude oil. The FPSO will be spread moored in approximately 2,000 meters water depth.