Australian offshore safety regulator NOPSEMA has approved Inpex's application to install Umbilicals, Risers and Flowlines (URF) infrastructure as part of the next stage of the development of the Ichthys gas and condensate field offshore W. Australia.

The scope of Inpex's plan includes the expansion of the subsea production system through the installation of a new gathering system and new infrastructure required to connect new production wells to the existing gathering systems.

The scope also includes the potential for inspection, maintenance, and repair (IMR) of existing and proposed infrastructure in WA-50-L; however, the start date is subject to vessel availability, operational efficiencies, and weather, Nopsema said.

The proposed activities will be carried out in the WA-50-L offshore license over a period of five years.

The start date is expected to be in Q1 2021, however, the exact timing for start and completion will be dependent upon approvals, vessel availability, operational efficiencies, and weather conditions.

According to the Inpex plan, a plethora of offshore vessels, such as installation vessels, deep-water construction vessels, derrick lay vessels, construction support vessels, light construction vessels, support vessels, platform supply vessels, survey/metrology vessels, tugs, barges, dynamically positioned (DP) transport vessels, offshore construction vessels, and heavy lift vessels will be used for the operations in multiple campaigns within a 5-year period.

Initial development wells were drilled and the Ichthys LNG offshore facilities were installed and commissioned from 2014 through to 2019.

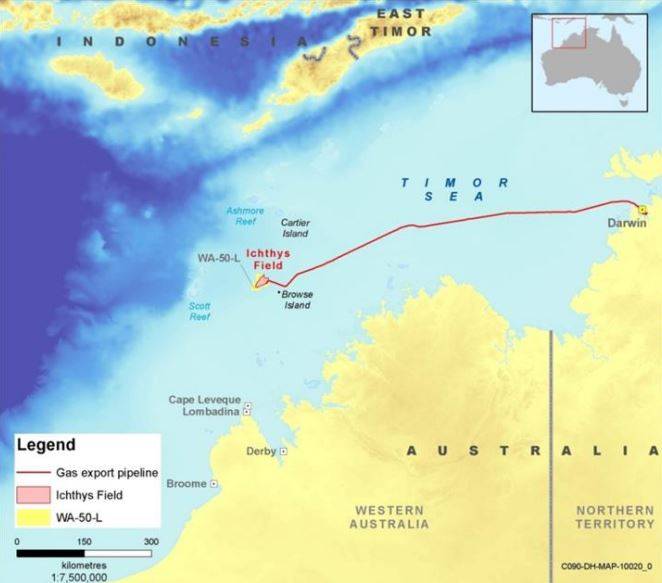

The Ichthys assets started production in July 2018 and now routinely ship cargoes of condensate from the Ichthys Venturer FPSO to international customers and send gas to the onshore plant in Darwin via the gas export pipeline (GEP).

The existing facilities consist of a subsea production system (SPS) (e.g. xmas trees (XT), manifolds, subsea control systems and umbilicals, risers and flowlines (URF), and the gas export riser base, which connect the development wells to the central processing platform (CPF Explorer) and floating production storage offtake (FPSO Venturer).