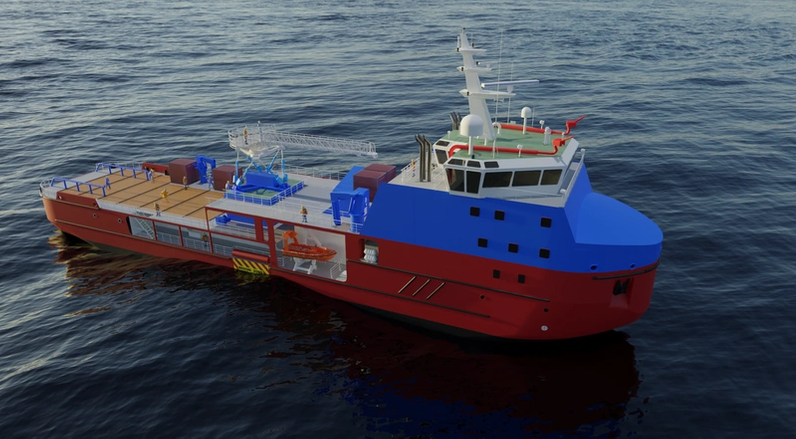

Dutch offshore crew transfer specialist Ampelmann will deliver an ice-strengthened gangway for the recently ordered, Russia-bound, shallow draft ice-breaking walk to work vessel.

As previously reported, Dutch shipbuilder Niestern Sander, with compatriot vessel-owner Wagenborg Offshore, signed a deal with Mercury Sakhalin and Pola for the construction of the vessel. The vessel is scheduled for delivery in 2021, and will serve the oil and gas industry in Russia's far east.

In a statement on Thursday, Niestern Sander said that Ampelmann, Royal Niestern Sander, and Royal Wagenborg signed an agreement for the supply of an ice-strengthened walk-to-work gangway for the vessel.

Together with the vessel, the motion-compensated gangway of Ampelmann will perform crew transfer services for up to 40 persons from the shallow Nabil Port to offshore platforms near the East Coast of Sakhalin. The vessel will be operated by Mercury Sakhalin.

The winterized A-type gangway is specially developed for the harsh environmental conditions at the East Coast of Sakhalin.

The new Ampelmann system is based on the proven technology and track record of the original A-type and utilizes the winter-proof features of the N-type. It is able to compensate waves up to 3 meters high and allow for safe and comfortable transfers at temperatures as low as -30°C.

The system will have two operating modes, in which it will be placed midship during the summer to ensure the highest motion compensation capabilities, and towards the stern of the vessel during the winter to accommodate people transfers while ice breaking.

Credit: Royal Wagenborg

"The integration between the gangway and the vessel is unique as the system has a winter and summer position by means of a skidding system. This optimizes the safe transfer of the crew changes and the workability of both the system and the vessel. In the winter the gangway is positioned aft as the vessel is operating in ice conditions with transfer direction over the stern. In the summer the gangway is positioned mid-ship for optimal workability. This dual-mode results in year-round operational support to the end client," Niestern Sander said.

As for the vessel itself, it is designed and optimized for year-round operations in the challenging conditions on the east coast of Sakhalin in temperatures ranging from -30 degrees to +35 degrees.

By combining a shallow draught of 3,15m, a transit draught of 4,0 m in open waters and a grounded bottom notation, the vessel can be deployed year-round. With Wagenborg icebreaking technology of the icebreaking hull and pulling (ice milling) Azimuth thrusters, the vessel can break through ice up to 100cm, Wagenborg said earlier in June.