Just as the oil and gas industry was starting to get back on its feet, COVID-19 and plummeting oil prices have affected the market across the board, including well intervention. But players in this space are optimistic, with new vessels and more compact intervention systems being planned and hopes that production enhancement will be an easy win for operators post-COVID.

The light well intervention (LWI) segment – from vessels, rather than rigs - struggled in the downturn, says Catherine MacFarlane, subsea analyst, Energy, at IHS Markit. The only long-term contracts are with Petrobras and Equinor, which means the market is reliant on seasonal shorter-term work and tends to be among the first to be affected in terms of rates and utilization. Yet, prior to COVID-19, 2020 was showing some very modest rate increases and a stabilizing market, she says.

Indeed, 2019 and into early 2020, riserless light well intervention (RLWI) activity had been steadily growing, says Tor Erik Grønlie Olsen, Country and Business Development Manager UK at TIOS (TechnipFMC/Island Offshore).

The UK and Norway have been RLWI heartlands, with five RLWI vessels in operation, but other regions had picked up too, says Olsen, such as West Africa, where riserless intervention operations (hydraulic and mechanical) amounted to more than 300 days – up from about 100 days per year – with three major oil companies performing multi-well campaigns across three countries at the same time. Indeed, in February, Oceaneering inked a significant RWLI services contact with BP over Blocks 18 and 31, offshore Angola, running from Q2 into late Fall. The Gulf of Mexico has also been busy, notes Olsen.

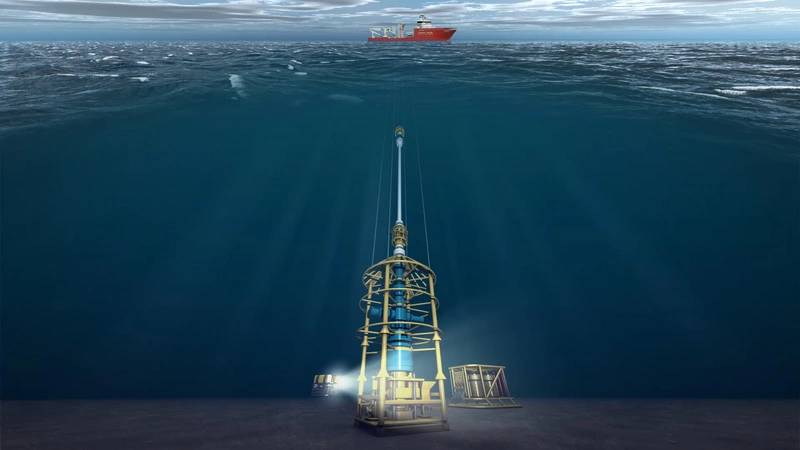

The DP3 MV Pride showing the Osbit Smart Tower System (Artist’s impression)

The DP3 MV Pride showing the Osbit Smart Tower System (Artist’s impression)

The current outlook, however, isn’t so great. “Operators very rapidly froze, delayed or cancelled operations, in an effort to preserve cash,” Olsen says.

Unlike subsea construction vessels, there are few other markets for dedicated LWI vessels to seek refuge in, says MacFarlane, and competition from rigs could be hard for semisubmersible units.

Units ordered in past years also remain idle. Newbuild semisubmersible intervention unit Etesco Interventor remains at the Dalian yard, China, after Petrobras and Etesco reached an agreement to cancel its charter in 2017, says MacFarlane. The PaxOcean yard is also still home to the newbuild semi Derwent, following the termination of a shipbuilding contract with Hallin Marine in 2014. To date, the Derwent is yet to find a buyer or work. At the same time, the Skandi Constructor, which was Marine Subsea’s Sarah and is now owned by DOF Subsea, has spent most of its recent working life as a walk-to-work vessel in the offshore wind market, despite still being equipped with a tower on board, says MacFarlane. That brings the total potential fleet size to 22 vessels, if there are no retirements, she adds, according to data from IHS’ ConstructionVesselBase.

Some active vessels could now be warm-stacked (some already are) with the risk that older units might never return to market, taking experienced assets – including people – out of play.

However, Owen Kratz, CEO of Helix Energy Solutions, told a recent investor event that the competition from rigs should be lower than it was through the last downturn, due to less rig overhang – the “sunk cost” operators had in rigs that they’d already committed to back then.

There’s also positivity. Carl Roemmele, Subsea Intervention - Executive Director, at Baker Hughes, says while some are “battening down the hatches” with deferrals, some operators are “embracing intervention harder than before, as it’s an instant hit to revenue if you can improve a well performance by 200-400% or tangibly extend field life.”

John Attenburrow, managing director at new entrant FTAI Ocean, says that once solutions or vaccines for COVID are available, there’s likely to be a focus on revitalizing aging subsea wells, as “well intervention presents one of the lowest cost per accretive barrel production.”

There’s also decommissioning work to be done, points out David Carr, Helix’s Senior Vice President, International Development. Indeed, last year, the global LWI fleet carried out 680 days of decommissioning/removal work, compared to 340 days in 2018 and 124 days in 2017, says IHS Markit’s MacFarlane, “and this is an area we would expect continued growth in,” particularly in the North Sea, she adds.

A successful maiden campaign for Q7000

Helix Energy Solutions has seven well intervention vessels across Europe, the Americas, and Africa. This year, it brought its newbuild semisubmersible, the Q7000, into service with its first project being a 10-week, five-well campaign offshore Nigeria in 1,220 m water depth. The project, completed 25 days ahead of schedule with 96.86% uptime, involved subsea workover and well intervention operations, including water shut off/zonal isolation; hydrate milling/coiled tubing clean up and remedial safety valve operations.

It was Helix’s first job offshore Nigeria and the first coiled tubing hydrate milling project done off the country’s shores. Going to press, the Q7000 was warm stacked in Tenerife looking for its next job, while the North Sea focused Seawell monohull was warm stacked in Leith, Scotland, having had contracts deferred or canceled. The rest of Helix’s vessels are on long-term contracts or contracted into Q3/ until the end of the year, and discussions are ongoing for work for the warm stacked units, the firm said in its Q1 update.

Helix Energy Solutions’ newbuild Q7000. (Photo: Helix Energy Solutions)

Helix Energy Solutions’ newbuild Q7000. (Photo: Helix Energy Solutions)

Driving RLWI uptake at operators

TIOS currently operates three LWI vessels. In 2019, it recorded a record of 81 well interventions in a year across its three riserless LWI systems.

In 2019 and into 2020, TIOS had new clients trying RLWI work for the first time. “Once they have directly experienced the efficiency and effectiveness of RLWI, many of them extend the work scope, add new wells and consider RLWI as the base case for more operations that were traditionally performed by the rig,” Olsen says.

Recent innovative projects include using an e-line stroker tool to remove and set crown plugs in horizontal trees in deepwater (SPE paper SPE-194241), using an e-line drilling tool to perform gaslift retrofit in an existing well in just three runs and acid fracturing operations at 60 bpm flowrate in simultaneous operations with a stimulation vessel.

The firm’s Island Frontier is currently available, after 14 years of continuous service for Equinor until last year, during which it intervened in more than 230 wells. Island Wellserver remains contracted to Equinor for a minimum of 200 days for another year, having started working for the major in 2009. Island Constructor continues to operate for several operators in Norway and in the UK and is expected to be busy for most of 2020. Replacing Island Frontier is AKOFS Offshore’s AKOFS Seafarer, under a five-year, year-round RLWI contract agreed in 2018 with Equinor, starting in 1H 2020. An RLWI system was recently delivered to AKOFS by Aker Solutions.

TIOS’ Island Wellserver (Photo: TIOS)

TIOS’ Island Wellserver (Photo: TIOS)

Introducing new intervention systems to market

Singapore-based FTAI Ocean has contracted UK engineering firm Osbit to design and build a Smart Tower System (STS) for the DP-3 vessel M/V Pride in a move that will evolve further the new designs Osbit had created for the Siem Helix 1 and 2 (OE: April 2017, Making a step change).

According to FTAI, the STS is for riser-based and RWLI in up to 1,500 m (4,921 ft) water depth. It’s built around an active, dual-level heave compensated platform, giving access to surface pressure control equipment, slickline, and e-line operations and for building, operating and recovering completions, 90 ft. workover riser joints and subsea pressure control equipment weighing up to 250-tonnes, with a mechanical and control interface to the vessel’s existing 250-tonne heave compensated crane and a vertical CWOR racking system. It’s set for delivery in Q1 2021, vessel installation in Q2 2021, then targeting projects in FTAI’s existing markets in the Asia Pacific region but also available globally.

Osbit director Steve Bedford says there’s a move towards installing these systems on to standard lighter, faster and cheaper vessels. The towers for the Siem Helix 1 and 2 were a huge step on that route, productionizing well intervention operations in an effective and safer way, and more will happen in this space.

First to open water coiled tubing market

Oceaneering, with one dedicated intervention vessel, the Ocean Evolution, plus systems it uses on other vessels, has been maintaining “a high level of activity.”

It has intervened on 20 wells hydraulically and mechanically over the past year to date, mostly in the Gulf of Mexico and West Africa, according to Ian Still, Oceaneering’s Service Line Manager, Intervention Services.

Furthermore, Oceaneering is set to finally demonstrate its open water coiled tubing (OWCT) capability – a new capability for the market - having progressed to proof of concept. The system comprises a subsea jack, to drive the coil into the well subsea, that will be tested later this summer, along with the coil, surface injector, and the controls for both systems. The nominal operational range for the system will be 2000 ft - 10,000 ft water depth.

“There are no current riserless live well coiled tubing options in the marketplace,” says Still.

“Our OWCT brings the advantages and capabilities of coiled tubing to an otherwise LWI spread. OWCT can be used as needed in conjunction with wireline, whether planned or contingency for live well operations.”

Oceaneering’s aim is to deploy the OWCT from suitable vessels of opportunity, offering 40% less footprint, reduced crew size (up to 60%), almost eliminating pre-engineering needs, and lowering total cost.

Expro’s new intervention riser system (IRS) being deployed offshore Mauritania. (Photo: Expro)

Expro’s new intervention riser system (IRS) being deployed offshore Mauritania. (Photo: Expro)

Building tracking record and vessel hunting

Expro has been increasing its weight in LWI. It last year acquired Norwegian coiled tubing, including open water coil hose, intervention firm Quality Intervention, and has launched a new intervention riser system (IRS) and a new riserless well intervention system (RWIS).

The IRS had been deployed on an estimated 360-day P&A campaign from Pacific Drilling’s Pacific Santa Ana drillship for Petronas in Mauritania, when the Malaysian oil firm in March declared force majeure on the rig contract. According to Expro, the Santa Ana is stacked in Las Palmas due to the current COVID-19 pandemic, however the base plan is to proceed back to Mauritania and recommence the P&A program when safe to do so, targeting early 2021.

To date, the IRS has been used on nine of the 15 wells in the program of 15 wells, recovering three subsea Xmas trees on the bottom of the IRS system and “bunny hopping” between the remaining six wells to perform intervention services

Expro had also announced an alliance with COOEC Offshore to bring the RWIS to market from a newbuild vessel, however that partnership is no longer in place, and an alternative vessel, as yet unnamed, will be used. The RWIS is currently being built, with final assembly and testing due at Expro’s Aberdeen facility before mobilization to Asia for vessel integration and testing ahead, with a first intervention campaign in Q2 2021, says Kevin Illingworth, Subsea Global Sales Director, Expro.

Expro’s riserless well intervention system (RWIS) (Image: Expro)

Expro’s riserless well intervention system (RWIS) (Image: Expro)

Building a broad spread, vertically and horizontally

Baker Hughes has also been flexing its muscle. Roemmele says the firm now has about 30% of the market capacity in intervention equipment focusing on large bore capacity with light-weight intervention and ultra-light-weight intervention through the life cycle. That’s after investing in a global fleet of 10,000 psi and soon to arrive 15,000 psi fluid skids that can be deployed from field support vessels to inject high-flow chemicals into vertical and horizontal trees to boost production.

In mechanical intervention from rigs, Baker has increased its offering in the completion work over riser and subsea test tree space, adding to its rental fleet.

Baker also acquired Wild Well Control LWI system stacks and put them straight to work on a six-well campaign.

“Add these to the existing fleet in Well Access, Baker Hughes now has around 30% of the global light well capacity,” says Roemmele. “Add the multi-WOCS (workover control system) capability and add our Well Services (wireline, chemicals, coil tubing, pressure pumping, and our reservoir expertise), and it’s a truly incorporated service offering.”

In the UK, since the Oil & Gas Authority’s (OGA) 2018 Wells Insight report highlighted low rates of well intervention activity as an issue (see OE: August 2019), 50% of operators have reported an increase in well surveillance activity, says Brenda Wyllie, the OGA’s Northern North Sea and West of Shetland Area Manager and now also co-chair of a new MER (Maximizing Economic Recovery) UK Wells Task Force. There’s also been a 20% increase in intervention spend, across surveillance and intervention activity, year on year (2018-2019). Reported production losses from wells also decreased for the second year in a row. However, there’s still 30% of active well stock shut in or mechanically plugged – an issue raised by the 2018 Wells Insight, and activity has dropped this year, due to COVID and low oil prices.

The new Wells Task Force has been set up to address issues around well activity and performance on the UK Continental Shelf. Within this group, five working groups are being set up to looking at: reservoir and wells optimization; right scoping; waste removal, seeking to reducing non-productive time and mechanical side-tracks; improved partnerships, to get, among other things, multi-operator campaigns; and decommissioning. The OGA is also now sharing wells related data and insights in the form of an online dashboard, says Wyllie, and an updated Wells Insight report is expected later this year.

Another initiative, Oil & Gas UK’s Unlocking Brownfield Resource Opportunities Guidelines, published in May, also touches on well intervention. Katy Heidenreich, the body’s Operations Director, says there’s a clear opportunity to increase the number of well interventions and unlock more barrels. Some of the issues holding up this work include how companies prioritize well intervention, among other operational demands, she adds.