As the maritime industry steams toward decarbonization, the path to zero emissions will include many stepping stones. Wärtsilä’s Compact Reliq is a step change in efficiently reliquefying boil off gas (BOG) on LNG carriers, as Lasse Wichstrøm and Sylvain Fabreguettes discuss with Maritime Reporter TV.

LNG carriers have, for years, utilized boil off gas (BOG) to help fuel the ship, even before ‘decarbonization’ and ‘emission reduction’ became lexicon in the maritime sector.

“Compact Reliq is not a brand-new product in the sense that reliquefaction plants have been around for some time,” said Sylvian Fabrequettes, Product Line Manager LNGC Systems, Wärtsilä Gas Solutions. “Wärtsilä has been a pioneer, introducing the reliquefaction technology to the markets back in 2005.”

But Compact Reliq is the latest evolution of LNG technology from Wärtsilä. “The Compact Reliq can help to improve the efficiency of the total chain and also the flexibility of the fuel, since we are able to handle the boil-off gas” to both fuel the ship’s main propulsion and auxiliaries, as well as to reliquefy the gas for return to the cargo tanks, said Lasse Wichstrøm, Sales Manager, Wärtsilä Gas Solutions.

“It's very simple,” said Wichstrøm. “It is about controlling the boil-off gas and, and the pressure and temperature inside the LNG tank. So onboard an LNG carrier, the amount of boil-off gas is higher than the gas amount needed for the engines for main propulsion and auxiliary power. So what we are doing is that we are taking that excess boil-off gas and re liquefying it (back to the cargo tanks).”

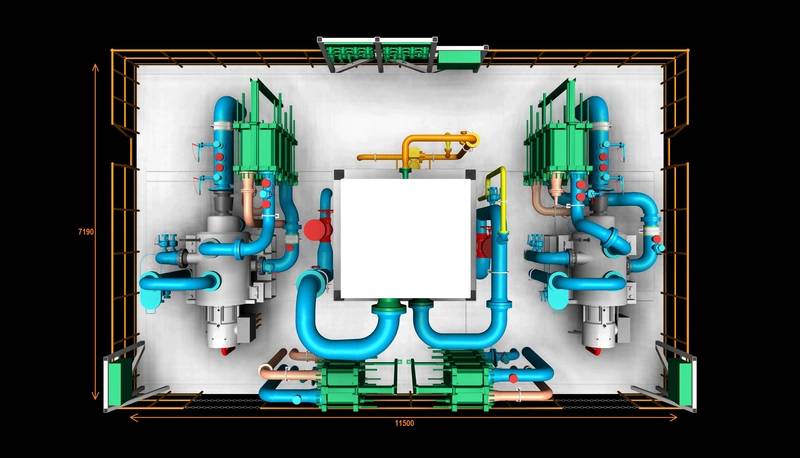

Compact Reliq is based on the reversed nitrogen Brayton cycle refrigeration technology, a solution designed to reliquefy the boil-off gas (BOG) from gas carriers and LNG bunker vessels, according to Fabrequettes, and for keeping the cargo cool under all operating conditions. The process is a closed nitrogen cycle for extracting heat from the boil-off gas, and typically, the reliquefaction system is used to control the cargo tank pressure by liquefying boil-off gas. The new system has the capability to handle all boil-off gas (100% capacity) or only excessive boil-off gas not burned in the engines (partly liquefaction).

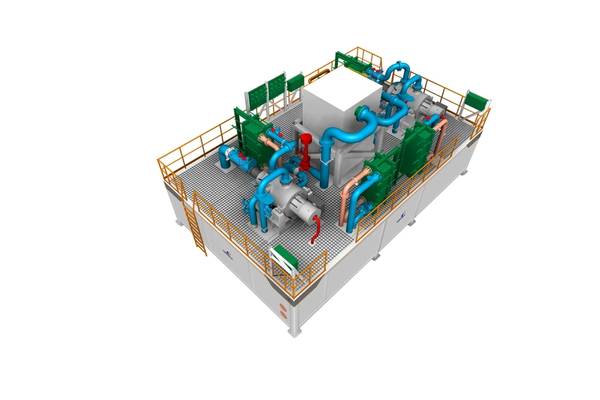

Wärtsilä’s Compact Reliq. Photo: Wärtsilä

Wärtsilä’s Compact Reliq. Photo: Wärtsilä

“It performs at about 850 kilograms per hour, in terms of BOG handling,” said Fabrequettes. “We have a booster option available in several process configurations that will increase the capacity to almost 1500 kilograms per hour. Then we are going to the CRD model, which is a Compact Reliq double, which performs at about 1700 kilograms per hour. (With this too) we can adopt a booster option, so it gives quite a good range.”

The system received its first commercial order in late 2020, to be installed on a pair of new 170,000 cu. m. LNG ships (with an option for two more) being built for Knutsen OAS Shipping at Hyundai Heavy Industries in South Korea. Both will be installed with the CRD unit with a capacity 1.7 tons per hour.

“This is a great contract for us, showing that the market is ready to embrace this new Brayton nitrogen technology,” said Fabrequettes. “we are working on several other opportunities with different shipyards, too.”

In the case of the Knutsen OAS Shipping contract, the system will be instrumented for remote monitoring and online operational support as part of Wärtsilä’s Operational Performance Improvement and Monitoring (OPERIM) program. The equipment is scheduled to be delivered to the yard commencing in February 2022, and the vessels are expected to begin commercial operations from late 2022.

Newbuild vs. Retrofit

As its name suggests, the system is compact, designed to make it easy to retrofit on existing ships without extensive modifications, and the refrigeration process uses safe and easily obtainable commercial grade nitrogen. With the system’s ability to efficiently control tank temperature and pressure, ships that traditionally have steamed at 20+ knots to help manage tank pressure are now able to slow down significantly, a double win for the bottom line and the environment.

“It is for both newbuild and retrofit,” said Wichstrøm. “The module itself it's designed for easy installation, regardless if it's a new build or a retrofit. And we see a big potential in both these markets. (When you look at a five- to 10-year-old large scale LNG carrier), “they have a lot of life left and could be a lot more efficient going at maybe 12-13 knots then going at 20 knots, as they have to do today to keep the tank pressure under control.”

The BOG reliquefaction system could be installed for vessels, offshore installations, or onshore facilities such as LNG terminals.