Norwegian energy company Equinor said Tuesday its Hywind Scotland floating offshore wind farm in the UK has, for the third consecutive year, reached the highest average capacity factor for any wind farm in the UK.

With an average capacity factor of 57.1% in the twelve months to March 2021, the floating offshore wind farm set a new record in the UK, Equinor said.

"During its first two years of operation, the wind farm achieved an average capacity factor of 54%. That compares to an offshore wind average in the U.K. of around 40%. The capacity factor is the ratio of actual energy output over a given period of time, to the maximum possible output. A higher capacity factor means lower intermittency and higher value," Equinor added.

"With this top of the charts performance, the Equinor-operated wind farm has truly proven the potential for floating offshore wind, paving the way for the UK’s announcement of 1GW of floating offshore wind to be developed in the UK by 2030," Equinor added. Map Credit: Equinor

Map Credit: Equinor

Equinor's Hywind Scotland is the world's first floating offshore wind in operation. The 30 MW Hywind Scotland pilot park, consisting of five 6 MW turbines, has been producing since 2017, demonstrating the feasibility of floating wind farms that could be ten times larger.

Equinor will soon operate the world's largest floating wind farm, the Hywind Tampen, in Norway.

"With Hywind Tampen onstream in 2022 Equinor will operate a third of floating offshore wind production worldwide," Equinor said.

In 2009, Equinor installed the first-ever floating offshore wind turbine, and Hywind Scotland followed in 2017 as the world’s first commercial floating offshore wind farm.

The Hywind Tampen, currently in construction, will also be the project ever to use wind energy to decarbonize offshore oil and gas production.

"In Equinor we are constantly striving to improve the performance of our assets, whilst ensuring we extract learnings to support future projects. The turbines on Hywind Scotland are covered in sensors, to extract as much data from the wind farm as possible. We’re monitoring everything from ballast, mooring, structural strains and the more regular wind turbine sensor data, looking at how best to optimise this innovative technology as we prepare to develop at scale.

"We’re sharing parts of this data across industry to help the advancement of the technology globally and more widely than just our own operations,” says Sonja Chirico Indrebø, plant manager for Hywind Scotland and Dudgeon, the bottom-fixed wind farm off the coast of North Norfolk, who also can show to strong results.

As the first project of its kind, the Hywind Scotland wind farm has provided valuable data and results that will help drive the whole industry forward, Equinor said.

“It’s great to see the results Hywind Scotland and the floating technology keeps delivering. The potential for floating offshore wind is huge. With access to deeper waters and therefore higher and more consistent wind speeds, floating offshore is not only an efficient way to generate electricity from wind, this exciting technology can also provide jobs and value creation for the countries supportive of floating. In the UK alone, we are talking at least 17000 jobs and £33bn GVA by 2050. We believe Scotland has the potential to build a globally competitive offshore wind industry, including a real chance to enhance the development of floating offshore wind,” says Sebastian Bringsværd, head of floating wind development at Equinor.

Cost Reduction

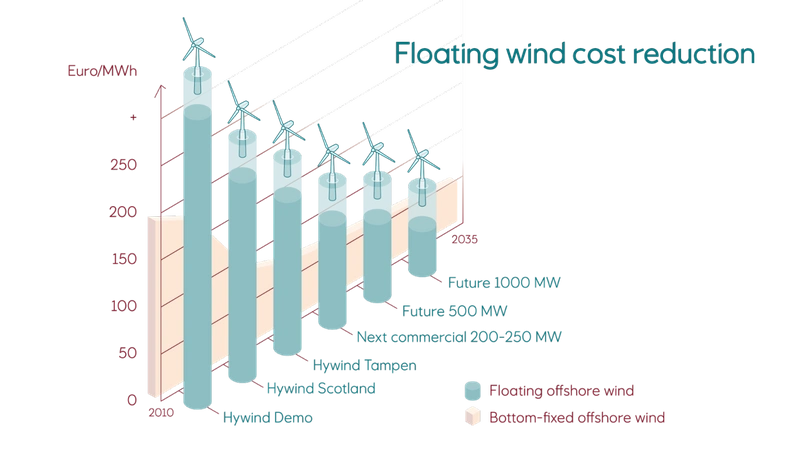

(Illustration: Equinor) Equinor said that scale is key to cost reduction, adding that the company has already seen a reduction in CAPEX per megawatt of 70% between its initial demonstrator, with a capacity of 2.3MW and Hywind Scotland, with a capacity of 30MW. The company expects a further 40% drop between Hywind Scotland and the 88MW Hywind Tampen.

(Illustration: Equinor) Equinor said that scale is key to cost reduction, adding that the company has already seen a reduction in CAPEX per megawatt of 70% between its initial demonstrator, with a capacity of 2.3MW and Hywind Scotland, with a capacity of 30MW. The company expects a further 40% drop between Hywind Scotland and the 88MW Hywind Tampen.

"The global energy industry has been pleasantly surprised by the rapid decline in the cost to deploy fixed bottom offshore wind. We’ve been working on floating offshore wind for more than ten years and we see that significant cost reductions can be achieved through scale and experience, paving the way for floating to become fully commercialized”, says Bringsværd.