As the offshore oil and gas industry becomes more competitive, it actively pursues increased efficiency through innovative approaches while streamlining production, reducing costs, and improving safety. Many companies are looking at digitization to insulate themselves from market shocks, remain profitable at lower oil prices, and generate competitive advantage during recovery. The path forward lies in leveraging machine learning-based technologies that are maturing quickly and are being adopted across the value chain. The use of Machine Learning (ML) models is particularly promising for the resolution of problems involving processes that are not completely understood or where it is not feasible to run mechanistic models at desired resolutions in space and time. With these growing technologies and solutions to complex science and engineering problems require novel methodologies that can integrate physics-based modeling approaches with state-of-the-art ML techniques. This paper provides an overview of the use of physics-based simulation models to test, correct, and retest ML algorithms under a range of scenarios and at a scale not practicable with physical testing.

Machine Learning (ML)

ML is the use and development of computer systems that use algorithms and statistical models to analyze and draw interferences from patterns in data to learn and adapt automatically through experience. It is seen as a subset of artificial intelligence. ML algorithms build a mathematical model based on sample data, known as “training data”, in order to make predictions or decisions without being explicitly programmed to do so. ML models search through a sample space of possible mathematical models, utilize methods to discern and adapt between such model choices with data to arrive at final model that best describes the data. This decision is based often times on pre-defined criterion to guide the search process.

Choosing the right ML model

ML models are beginning to play an important role in advancing discoveries in complex engineering applications that are traditionally dominated by mechanistic models. Selecting the right ML algorithm to accommodate the complexities of a real system that are not completely understood can be challenging. No single ML algorithm fits all scenarios. There are several factors that can affect the selection of a ML algorithm, including the complexity of the problem, type of data (structured, un-structured, texts, time series, images, etc.), and latency requirement for decision making (real-time, or offline analysis). A high volume of real-world data and testing is usually required but the data may not always be available. However, the absence of high-quality labelled data may result in inaccurate ML algorithms. In such scenarios, solving complex problems requires novel methodologies that can integrate prior knowledge from physics-based models with ML techniques.

Hybrid physics ML Model

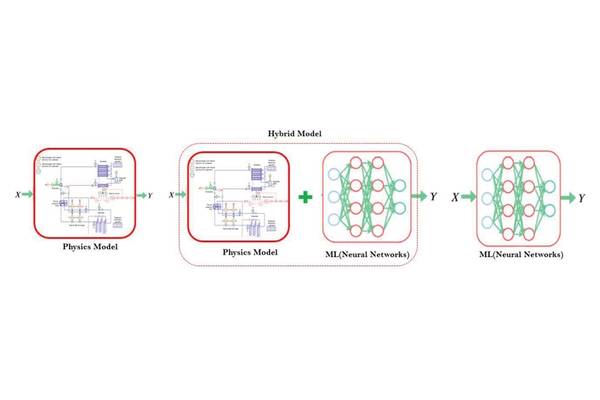

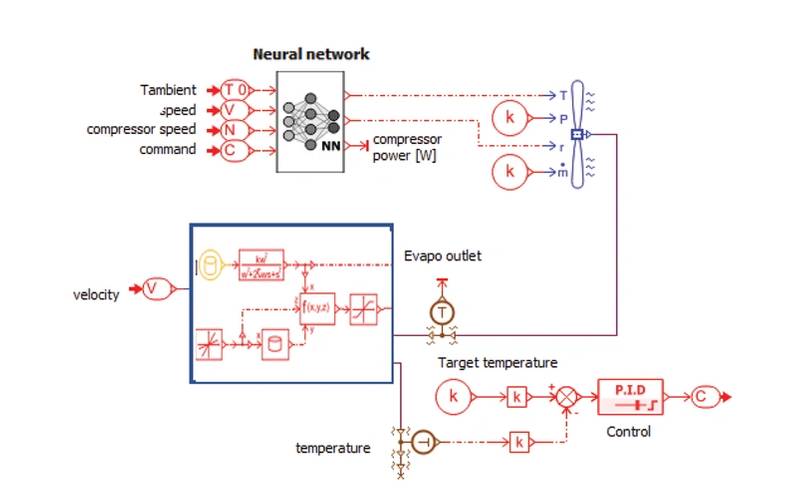

The hybrid modeling approach is a way of combining physics-based models with ML where both can operate simultaneously and can be decoupled in some way to improve the performance separately. See fig1.

Improving predictions beyond physics

First principal physics-based models are extensively used in wide range of engineering applications. However, physics-based models require strict boundaries and assumptions to create an idealized approximation of reality. These approximations can be hindered by incomplete knowledge of certain processes or unaccounted physical phenomena which can introduce additional bias. Often, the input parameters may have to be estimated through observed data.

When provided enough data, ML neural network models have shown to outperform physics-based models where complexity prohibits the explicit programming of the system’s exact physical nature. ML models can find structure and patterns in complex problems where physical processes are not fully understood. In resolving and improving the performance of complex engineering systems, physics-based models can be combined with state-of-the-art ML models to leverage their complementary strengths. Such integrated physics-ML models are expected to better capture the dynamics of complex systems and advance the understanding of underlying physical processes.

Hybrid ML model approaches

There are many ways to combine physics-based models with ML models, to train the ML model or to solve complex engineering applications. The three most common hybrid approaches (combining ML with SIM models) are discussed below:

1.ML after simulation run

2.ML prior to simulation

3.ML assisted simulation

Fig 5: Hybrid Model workflow in SIM

Fig 5: Hybrid Model workflow in SIM

ML after the simulation run

The results from the physics-based simulation model can be used as data input for the ML model in a system of approaches. This can be used in advanced ML algorithm training, such as fully autonomous operations. The simulation results incorporate known knowledge and constraints from physics domain (e.g. parameter correlations, decision metrics, importance and weighting on parameters, etc.) into the ML algorithm to constrain the learning space. You train the models not only with real system (Physics Models) but let the ML “drive” through complex solutions.

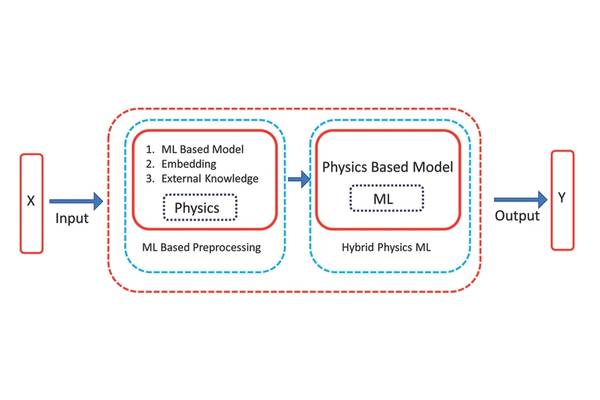

ML prior to simulation

ML models can be used to provide parameterization inputs to physics-based models. In a system of systems, ML may be applied on certain systems, but other connected systems may be represented with a physics-based model. Complex physics-based models often use an approach for parameterization to account for missing physics. In parameterization, specific complex dynamical processes are replaced by simple physics approximations whose associated parameter values are estimated from data. The failure to correctly identify parameter values can make the model less robust, and errors that result can also feed into other components of the entire physics-based model and deteriorate the modeling of important physical process. The ML model can be used to learn new parameterizations directly from observations and/or model simulation. A major benefit that can come from using ML based parameterization is the reduction of computation time compared to traditional physics-based simulations.

ML assisted simulation

This architecture explores the best combination of using ML and data emanating from the physics-based simulations. In this approach ML can be integrated into physics-based simulation by connecting the output of the Simulation model into particular nodes of the ML or by making the ML model learn aspects of the physics-based system and apply that learning directly. This approach effectively provides data-driven decisions to the entire system of systems.

Data Driven ML control for DP

Dynamic Positioning (DP) can be one example where the operation of vessel systems can benefit from ML algorithms.

Ships that are involved in safety-critical operations related to drilling, cargo-transfer, subsea crane operations and pipe-laying typically have an extended actuator setup to allow for redundancy in case of system errors. During such operations, the vessel is required to control its position and heading. DP of ships is a control mode that seeks to maintain a specific position (station keeping) or perform low-speed maneuvers.

A data driven control ML approach can be applied to resolve the problem of DP in an over-actuated ship subject to environmental forces. This control approach improved the overall ships performance criteria leaving the human decision to the top of the hierarchical DP control structure.

A hybrid modelling theme as discussed in this paper, that combines the ML data model with the prior knowledge physics-based model can help find solutions and improve the performance.

SIM tool to train and test ML

Physics based SIM models can help, to train and test the ML algorithms by:

1.Simulating near real world data

2.Testing different ML algorithms

3.Testing the quality of the data sources

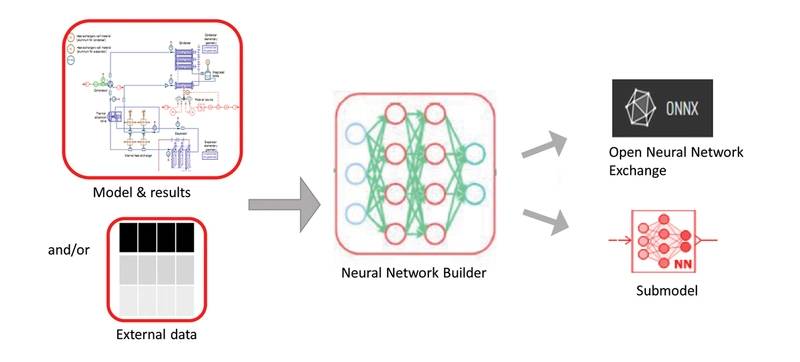

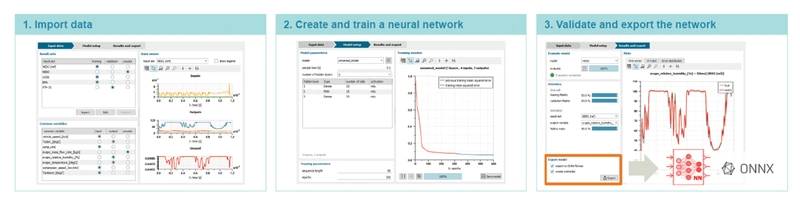

This approach provides full control over the data provided to the ML, both parameters contained within the data and the volume and frequency of the data. The SIM tool neural network module as shown in fig 5 & fig 6, can help to train and test the ML algorithm. If output of the ML is not acceptable changes can be made to the algorithm and the ML module can use these changes to upgrade and segment the rules in the ML model. This process continues until a satisfactory output is obtained. The Neural Network Builder in SIM tool creates neural networks from simulation models or external data sets. Neural networks provide a functional and compact representation of input-output relationships which mimics the complex behavior of the underlying model. Creation of a neural network is executed in 3 main steps as shown in fig 6:

1.Import of simulation results from a physics model

2.Use results from sim model for training of multi-layer networks

3.Validation of trained networks with fidelity metrics and plots

Once trained, the network can be exported as a submodel or as an ONNX file.

The Marine and Offshore industries are adopting state of the art ML concepts to improve vessel efficiency and performance. This paper describes the combination of ML and physics-based simulation as a hybrid approach fostering intelligent analysis of applications that can benefit from a combination of data-driven and knowledge-based approaches. Choosing the right ML algorithm to accommodate the complexities of a real system is challenging. A high volume of real-world data and testing is usually required in choosing the ML, but the data may not always be available. In this paper ABS describes how SIM tools can be used in solving the problem of real-world data hunt by connecting prior knowledge physics-based models with an ML model. We explain how these sim tools can be used to train the ML, test the ML, and make corrections and retest the ML algorithm under a range of scenarios at a scale not practicable with physical testing. A hybrid model workflow connecting physics-based model to train the multi-layer neural network (one of the most known ML algorithms) is shown as an example. ABS as a Class Society believes simulation will play an important role as the industry adopts ML.

Fig 6: Example of a Neural Network Builder using SIM tool.

Fig 6: Example of a Neural Network Builder using SIM tool.

Fig 6: Example of a Neural Network Builder using SIM tool.

Fig 6: Example of a Neural Network Builder using SIM tool.