Classification society ABS has published guidance on the application of additive manufacturing (AM) in the marine and offshore industries.

The ABS Guide for Additive Manufacturing focuses on two main categories of metal AM processes: Powder Bed Fusion and Directed Energy Deposition. The Guide defines the ABS approval and certification process for AM facilities and AM parts by providing standards for AM design, feedstock material, building processes, inspection and testing. The Guide includes a strong focus on the quality of the materials and of the manufacturing process, both of which are key elements of the ABS process.

“This exciting technology can shrink the supply chain and lead times for specialized and complex parts as well as introduce new efficiencies driven by design innovation, reduced manufacturing time and improvements in parts availability. It clearly has a significant role to play in the future of the marine and offshore industries, and ABS is committed to supporting its safe, efficient and sustainable adoption,” said Patrick Ryan, ABS Senior Vice President, Global Engineering and Technology.

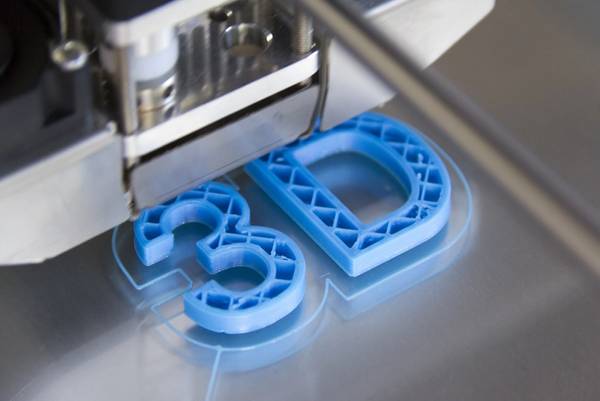

Also known as 3D printing, AM is a process of fusion/joining materials to make objects from 3D model data, usually layer upon layer. AM can fabricate 3D parts by creating multiple 2D cross sections and increase the flexibility of designs for complex shapes, some of which were not previously feasible in traditional manufacturing.

ABS has been supporting the industry with the introduction of AM since 2017, when it published an Advisory that provides an overview of metal AM technologies, technical challenges and tradeoffs, changes to the design process, quality and reliability. In 2018, ABS released new Guidance Notes that establish a consistent approach for qualifying AM systems and facilities to produce parts for the marine and offshore markets.

ABS is today involved in a number of industry-leading AM initiatives, including a joint development project with Sembcorp Marine, 3D Metalforge and ConocoPhillips Polar Tankers Inc. to fabricate, test and install functional AM parts on board an oil tanker. ABS is also leading a joint industry project with ShipParts.com and 3D Metalforge to develop valve and pump parts for use on board a PACC Offshore Services Holdings Offshore Support Vessel, using the AM material approval process.