Dogger Bank is not simply an offshore windfarm project, it is THE offshore windfarm project. Dogger Bank is an offshore wind farm site in the UK North Sea that will, once fully built, be the world's largest and most innovative. Here Offshore Engineer breaks down the main elements and players in the project.

Located 130km off the Yorkshire Coast, the 3.6 GW offshore wind project will consist of three phases – each at 1.2GW, and will cover an area of 1675 km2, larger than Greater London.

The three phases were previously known as Creyke Beck A, Creyke Beck B and Teesside A.

In February 2020, the UK-based SSE and Norway’s Equinor, which at the time owned the project at 50 percent stake each, decided to change the respective names to Dogger Bank A, B, and C, to recognize the wind-farm-site-to-be's connection to the ancient area Doggerland, which once connected the UK with the mainland Europe, and which was home to a Mesolithic community who lived around 12,000 years ago.

"The area was made up of hills, marshland, wooded valleys and swampy lagoons and was home to hunter-gathers. The end of the last ice age brought flooding to the area, followed by a catastrophic release of water from a glacier, removing what was left of this land. From this ancient area today remains Dogger Bank, a large sandbank in a shallow area of the North Sea between 125km and 290km off the North East coast of England," SSE and Equinor said early in 2020, announcing the name change.

The UK's Renewable Energy Ambitions

The project is seen as a centerpiece of the UK government ambitious goal to reach 40GW of installed offshore wind capacity by and have every home in the UK powered by offshore wind by 2030. The three phases of the Dogger Bank Wind Farm, will deliver enough power for six million UK homes.

The Dogger Bank offshore wind development last year secured financing for the first two phases, which involved support from no less than 29 banks and three export credit agencies in what was dubbed the world largest offshore wind project financing, with $7.5 billion secured.

“Reaching financial close on the two first phases of Dogger Bank is a major milestone, demonstrating our commitment to profitable growth within offshore wind. The extensive interest from lenders underpins the attractiveness of UK offshore wind assets and confidence in SSE and Equinor. As the wind farm’s future operator, we are proud to take this big step forward in delivering what will be the backbone of a growing wind hub in the North Sea,” Pål Eitrheim, Equinor’s executive vice president of New Energy Solutions, said at the time.

The financial close for Dogger Bank C is expected in late 2021.

The Dogger Bank project, for which The Crown Estate awarded development rights for fifty years in 2010, was granted consent as a Nationally Significant Infrastructure Project in 2015. A few years later, in 2019, the Dogger Bank then successfully secured 15-year contracts (CfDs) for 3.6GW of new offshore wind energy in the UK Government's auction for low carbon power in 2019. The strike price will be paid for every MWh generated by the wind farms during the contract.

The CfD terms, as shared by SSE are below:

SSE and Equinor in 2020 then sanctioned the development of the first two phases, awarding major contracts and subsequently welcoming a new partner, Italy's Eni, into the Dogger Bank A and B, where SSE now owns 40, Equinor owns 40 and Eni has 20 percent, for which it paid $750 million.

“For Eni, entering the offshore wind market in Northern Europe is a great opportunity to gain further skills in the sector thanks to the collaboration with two of the industry’s leading companies, and to make a substantial contribution to the 2025 target of 5 GW of installed capacity from renewables, an intermediate step towards the more ambitious target of zero net direct and indirect greenhouse gas emissions in Europe by 2050,” said Claudio Descalzi, Chief Executive Officer of Eni.

The third phase is still owned 50:50 by Equinor and SSE. SSE is lead operator for the development and construction phases of the Dogger Bank wind farm.

Size Matters

Apart from being the world's largest wind farm, securing world largest offshore wind project financing, being located in the world's largest offshore wind market – the UK, the Dogger Bank will feature GE’s GE Haliade-X wind turbine, which will, once installed be the world's largest and most powerful wind turbines in operation.

For the first two phases, GE will deliver 190 Haliade-X 13MW offshore wind turbines, split evenly at 95 turbines for each of the two phases. These will be an enhanced version of GE’s 12MW prototype unit which has been generating power in Rotterdam since November 2019.

The installation of these turbines will be the first time ever a 13MW Haliade-X is installed in the world. "One spin of the Haliade-X 13MW can generate enough electricity to power a UK household for more than two days," Equinor said in September 2020. For some color on where the offshore wind industry was starting off – bear in mind the 13MW capacity of a single Haliade-X turbine - the world's first offshore wind farm Vindeby in Denmark had a total capacity of 5MW, coming from eleven turbines.

Back to the Haliade-X giants. While having these goliaths installed for the first time is/will be a feat worth boasting about, the world's largest turbines are not there just for bragging rights.

Rystad Energy last year published an analysis that showed that the largest offshore wind turbines, while more expensive, reduce the overall cost of large-scale offshore wind farm development.

For the Dogger Bank Phase C, which has yet to be sanctioned, GE has also been selected as a preferred supplier, too. This phase, while expected to be 1.2 GW, the same as the first two, will have fewer wind turbines installed. Namely, GE will deliver an “uprated” version of the Haliade-X turbine type, with a 14MW capacity.

"Utilizing 14 MW turbines instead of 10 MW ones, the number of units required for a 1 GW project falls by 28 units, from 100 to 72. Moving to a 14 MW turbine from a 12 MW turbine still offers a reduction of nearly 11 units. Overall, the analysis shows that using the largest turbines for a new 1 GW wind farm offers cost savings of nearly $100 million versus installing the currently available 10 MW turbines," Rystad found.

GE Renewable Energy will establish its marshaling harbor activities at Able Seaton Port in Hartlepool, serving as the base for turbine service equipment, installation, and commissioning activities for Dogger Bank A and B.

The port will see the delivery of component parts for each of GE’s Haliade-X 13MW wind, including the nacelle, three-tower sections, and three 107m long blades, for pre-assembly on-site at Able Seaton prior to transport out to the North Sea for installation.

"This activity will lead to the creation of 120 skilled jobs at the port during construction,” Equinor said in September 2020, announcing the contract with GE.

GE also has a five-year service & warranty agreement to provide operational support for the wind turbines. GE’s Service team will be co-located with the Dogger Bank Operational and Maintenance team, based out of the Port of Tyne.

What is more, GE in March 2021, said its subsidiary LM Wind would open a new wind turbine blade manufacturing facility in Teesside in the North East of England, dedicated to the production of its 107-meter- long offshore wind turbine blades, a key component of GE’s Haliade-X wind turbines. LM Wind's 107-meter blade Credit LM Wind GE Renewable Energy estimates that this new plant, set to open and start production in 2023, could create up to 750 direct renewable energy jobs and up to 1,500 indirect jobs in the area. Dogger Bank Wind Farm Project Director, Steve Wilson, said the Dogger Bank Wind Farm was the anchor project for the blade facility announcement by GE.

LM Wind's 107-meter blade Credit LM Wind GE Renewable Energy estimates that this new plant, set to open and start production in 2023, could create up to 750 direct renewable energy jobs and up to 1,500 indirect jobs in the area. Dogger Bank Wind Farm Project Director, Steve Wilson, said the Dogger Bank Wind Farm was the anchor project for the blade facility announcement by GE.

“Dogger Bank Wind Farm is a world-leading development pushing the boundaries of offshore wind development and playing a key role in delivering the ambition to increase UK supply chain capacity and capability. Through our turbine supply order with GE, the Dogger Bank project is the catalyst for this important GE investment in Teesside, harnessing skills and expertise in the local area and delivering long-term benefits in the UK’s offshore wind sector,” Wilson said.

It is expected that a substantial number of Haliade-X blades for Dogger Bank Wind Farm will be among the first orders to be delivered from the new manufacturing plant. Blades produced at Teesworks will be installed from 2024 onwards with the final number of blades from the plant destined for Dogger Bank to be confirmed in due course.

The importance of Dogger Bank goes beyond just the ports and wind turbines. The project is important for offshore services suppliers, vessel owners, and shipyards in Asia, too, as the giant wind farm with its giant turbines requires giant vessels to build it.

This is a good opportunity to remember Chief Brody, from the 1975 movie Jaws, who, upon seeing a giant shark behind the Orca vessel, said: ”You’re gonna need a bigger boat.”

Voltaire Credit Jan De NulVoltaire – The Biggest “Boat”

Voltaire Credit Jan De NulVoltaire – The Biggest “Boat”

Luxembourg-based offshore installation contractor Jan De Nul Group (JDN) in April 2019 ordered the largest jack-up installation vessel ever seen in the industry, on the back of the forecast that the available jack-up fleet wouldn’t be able to handle the behemoth wind turbines of the – not so distant- future. It named it Voltaire, after the French writer, historian, and philosopher.

The four-legged Voltaire, equipped with a DP2 system, is designed to transport, lift and install offshore wind turbines, transition pieces and foundations.

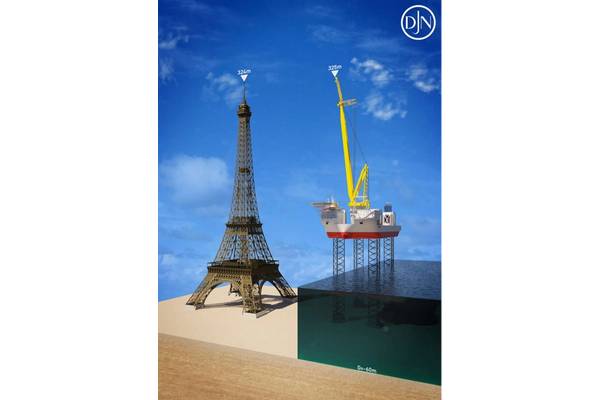

“For many current installation vessels involved in the construction of offshore wind farms, next-generation turbines present new challenges due to growing sizes and installation heights, as well as ever-increasing foundation dimensions. These new larger turbines can be more than 270 meters high and are fitted with blades of 120 meters long.

“With a crane capacity of over 3,000 metric tons, an operating depth of approximately 80 meters and a payload of about 14,000 metric tons, Voltaire is specifically designed to help handle these challenges, JDN said at the time,” announcing the order for the vessel which will be taller than the Eiffel tower.

For the Voltaire, the Dutch firm Huisman has been selected to design, construct and deliver “the biggest leg encircling crane ever installed on a wind turbine installation vessel.”

Following the vessel order, Jan De Nul didn’t have to wait long to secure the first contract. In October 2019, it was announced that the Voltaire would debut on, you guessed it, the Dogger Bank, with the firm contract signed in August 2020 for the Voltaire to transport and install the GE Haliade-X offshore wind turbines at Dogger Bank A and Dogger Bank B, with the work kicking off in 2023.

Interestingly, the vessel was ordered in April 2019, but the keel-laying ceremony for the 169.3 meters long jack-up was held in China almost two years later, late in March 2021.

Offshore Engineer reached out to Jan De Nul for an explanation.

“Let’s say that COVID-19 has been a true challenge the past year. A challenge which we manage. In any case, the project is currently on schedule," Heleen Schellinck, a Jan De Nul spokesperson said. “On schedule” means that the vessel is still expected to be delivered in 2022, ahead its 2023 debut at the Dogger Bank. The vessel will install the wind turbines on monopile foundations, to be built by a joint venture between the Sif Group and Smulders.

Sif will be responsible for the fabrication and supply of 190 monopiles and primary steel for the transition pieces, as well as for the marshalling of all foundation components. Smulders will be responsible for the supply, fabrication and fit-out of the secondary steel for the transition pieces.

Alfa Lift

Enter Offshore Heavy Transport. The Norwegian company specializes in, as its name suggests, offshore heavy transport. However, apart from just transport, the company will soon dive into the offshore installation work too, and will be responsible for the installation of the foundations on the Dogger Bank. (Click Here to see complete story on OHT and Alfa Lift in our interview with Torgeir Ramstad, CEO, OHT)

SOVs

Being far from shore means the wind farm will, once built, need to be serviced from large Service Operation Vessels, rather than by crew transfer vessels which are used to transport small crew of technicians to wind farms closer to shore.

SOVs, dubbed floating warehouses/hotels with walk-to-work turbine access are able to stay at the wind farm site for weeks, reducing transport and transfer time, and only come ashore to replenish supplies and equipment. Also, given that there’s no need to transport technicians from shore every day, and that they can basically “walk-to-work” via a gangway, this means that they have more time out on the turbines. Also, SOVs are equipped with a daughter craft used to move technicians round the wind farm to more remote turbines.

SOV Credit North Star RenewablesFor the Dogger Bank, Aberdeen-based firm North Star Renewables in March 2021 secured contracts worth an estimated £270 million (~$375 million), to deliver three state-of-the-art service operation vessels (SOVs). North Star will deliver the SOVs from summer 2023, with vessels chartered for a ten-year period, with an option for three one-year extensions.

SOV Credit North Star RenewablesFor the Dogger Bank, Aberdeen-based firm North Star Renewables in March 2021 secured contracts worth an estimated £270 million (~$375 million), to deliver three state-of-the-art service operation vessels (SOVs). North Star will deliver the SOVs from summer 2023, with vessels chartered for a ten-year period, with an option for three one-year extensions.

The UK-based firm said the deal would create 130 new full-time UK-based jobs in crewing and shore-based roles for the lifetime of the contract.

In support of the contract, North Star said it would establish a new permanent presence at Port of Tyne, "delivering a local economic and supply chain boost to the coastal region."

One SOV will be used for scheduled maintenance at Dogger Bank A and B. The vessel is due to be delivered in January 2024 and will also serve Dogger Bank C when this phase of the wind farm is operational.

Two other SOVs will be delivered by North Star to be used for corrective maintenance, at Dogger Bank A and Dogger Bank B. Delivery of these vessels is scheduled for July 2023 and July 2024 respectively.

The vessels will be built by Norway’s VARD at its shipyard in Vung Tau, Vietnam.

According to the shipbuilder, the hybrid vessels will be equipped with a diesel-electric propulsion system, highly efficient main propellers, and tunnel thrusters with permanent magnet electric motors in combination with SeaQ solutions supplied by Vard Electro in Norway. Living Stone Credit DEME

Living Stone Credit DEME

Cables

Belgium-based offshore installation services company DEME Offshore will deliver and install inter-array cables for the Dogger Bank A&B. The contract to deliver these cables connecting the turbines was described by Deme as a “substantial” one, meaning it’s worth between 150 million and 300 million euros.

"The far-reaching scope includes the engineering, procurement, construction and installation of the subsea cables for the combined 2.4 GW wind farm. Deme Offshore will supply, install and protect 650 km of 66 kV inter-array cables and all related accessories," DEME Offshore said.

DEME will use its DP3 cable installation vessel ‘Living Stone’ to install the cables, which apart from its large cable capacity of 10,000 tonnes, features a “dual-lane” system one for laying the cable and one where the next cable can be simultaneously prepared and have the cable protection system (CPS) installed. This, per Deme, reduces the time needed for preparing the cables, minimizes manual handling, increases the vessel’s workability, and ultimately, improves production rates.

The inter-array cables will be built by Hellenic Cables at its plant in Corinth, Greece. As for the export cables, the Dogger Bank consortium awarded the contract worth 360 million euros to NKT.

The export cable system comprises the construction of around 4x175 km of 320 kV DC offshore export power cables and 4x32 km of 320 kV DC onshore export power cables as well as installation by the 2017-built cable-laying vessel NKT Victoria, for which NKT says is “the world's most advanced cable-laying vessel.” The power cables will be manufactured in Karlskrona, Sweden.

Among many firsts related to the Dogger Bank project, it is worth mentioning that the Dogger Bank will be High Voltage Direct Current (HVDC) connected wind farm in the UK due to its distance from shore.

An artist impression of an offshore wind farm with an Aibel convertor platform, Picture source: Aibel

An artist impression of an offshore wind farm with an Aibel convertor platform, Picture source: Aibel

For this, the Dogger Bank consortium have selected Aibel and Hitachi ABB Power Grids to deliver offshore platforms and associated transmission links for all three phases of the project, the third being subject to an FID. Hitachi ABB Power Grids will install its compact high-voltage direct-current technology, called HVDC Light, for efficient transmission to the project’s onshore grid connections in the East Riding of Yorkshire for Dogger Bank A and B, and on Teesside for Dogger Bank C. Aibel will build the offshore converter platforms.

“An HVDC connection will ensure the renewable energy being transmitted over the long distances from the Dogger Bank offshore to the onshore grid connections in East Riding and Teesside, which will be achieved efficiently while minimizing losses,” Aibel and Hitachi ABB Power Grids explained.

Italian offshore services giant Saipem will be responsible for the installation of two offshore HVDC platforms for the first two phases. Saipem will use its Saipem 7000 crane vessel to install the platform consisting of a 2,900-tonne jacket and a 8,500-tonne topside.

Dogger Bank to supply 5% of UK electricity demand

Onshore works at the project began in 2020, while the offshore installation works at the Dogger Bank are expected to start in 2022.

First power is expected in summer 2023 for Dogger Bank A, and in and summer 2024 for Dogger Bank B and B, with commercial operations to follow around 6 months later. Turbine installation for Dogger Bank C is expected to begin in 2025, with the overall wind farm expected to be completed in 2026.

According to SSE, when fully complete in 2026, Dogger Bank Wind Farm will produce enough renewable electricity to supply 5% of UK demand and power up to six million homes each year.

SSE and Equinor in 2020 signed 15-year offtake Power Purchase Agreements (PPAs) for the first two phases of the Dogger Bank.

Separate PPAs for a total of 2.4GW across both Dogger Bank Wind Farm A and B have been concluded with external offtakers Ørsted (40% share) and Shell Energy Europe Limited (20% share), and with sponsor offtakers Danske Commodities (20% share) on behalf of Equinor, and SSE Energy Supply Limited (20% share) on behalf of SSE Renewables.

Following the completion of the construction, the operatorship over the Dogger Bank wind farm will transfer from SSE to Equinor. Equinor will then be lead operator of the wind farm for the duration of the wind farm’s operational phase of up to 35 years.

Worth noting, Equinor, known for years a Norway’s largest oil company, is working to transform itself into a broader energy company, with a goal to become “a global offshore wind major.” The company expects to increase its current installed capacity to 12-16 GW, around 30 times the current level, by 2035.