As the world has been shut down in stages due to COVID for the past 18 months, the same can’t be said for innovators in the offshore energy sector, many of whom will be honored in Houston August 16-19, 2021, with an OTC Spotlight on New Technology Award.

If you read Offshore Engineer regularly, OTC needs no introduction. Better yet, if you’re reading (the print edition!) right now, you are probably in Houston at OTC, as this is where the July/August edition of Offshore Engineer (barring any unforeseen circumstances) is being distributed.

At its peak in 2014, OTC drew more than 100,000 attendees from more than 100 countries, and while I’ve yet to attend personally, I’ve wanted to. For a journalist whose beat is offshore energy, this is like attending the Champions League finals. Despite covering the international offshore energy industry since 2010 and visiting other industry events in Houston and globally, OTC and yours truly have yet to meet face-to-face.

I came close in early 2020, when I joined Offshore Engineer and my new firm’s editor & associate publisher, Greg Trauthwein, called and said “pack your bags for Houston.”

But then, COVID 19.

In March 2020, the U.S. Embassy in Sarajevo – where I’m based – suspended visa applications and canceled my scheduled appointment. ‘There is still time,’ I thought, ‘this will blow over in a few weeks and I’ll make it to the OTC, learn about exciting tech advancements and share it with our readers extensively.’ But it wasn’t to be.

Just two days after my visa appointment was canceled, OTC organizers pushed to the third quarter of 2020, and eventually, as you know, canceled the 2020 event

Fast forward to 2021 and OTC, traditionally held in May, has been moved to August 16-19. Hopefully, you’re reading these lines from the NRG Park.

For me, this year too will, unfortunately, be another year where I’ll miss OTC, but I’m keeping my fingers crossed for 2022, and the chance to learn more on the technology developments, and to meet the people behind the tech face-to-face, over a beer (or two)!

The OE crew will be in Houston this year, so stop by booth #2726 to pitch your story threads to Greg and the OE team. For myself, I’ll borrow the outro line from seemingly everyone on YouTube: “I’ll catch you guys in the next one!”

But before I go, there’s something else you need to know (this is actually what you need to know, really!)

For each edition of the event, winners of the prestigious OTC Spotlight on New Technology Award are announced. This year is no different, with 14 technologies from 13 companies around the world selected, including five companies receiving small business recognition. Read all about the winners on the next four pages.

Here are the winners:

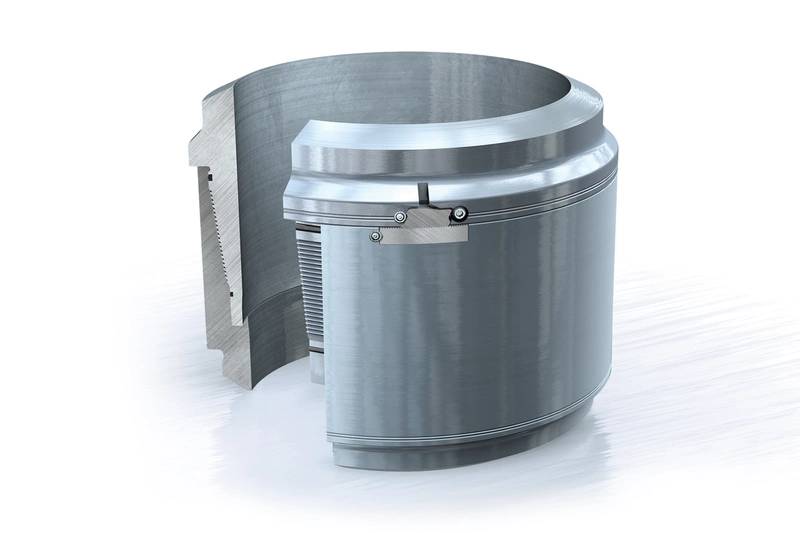

Dril-Quip, Inc., producer of Dril-Quip BADGeR Connector Image courtesy Dril-QuipThe Dril-Quip BADGeR Specialty Casing Connector dramatically reduces HSE risks and improves well economics. It features an automatic hands-free anti-rotation device that enables remote make-up, removing rig personnel from the red zone and eliminating the need for hand tools.

Image courtesy Dril-QuipThe Dril-Quip BADGeR Specialty Casing Connector dramatically reduces HSE risks and improves well economics. It features an automatic hands-free anti-rotation device that enables remote make-up, removing rig personnel from the red zone and eliminating the need for hand tools.

It effectively lowers the risk of injuries and hardware damage caused by dropped objects and missing components while reducing operating expenses. The BADGeR Connector makes up in 15 seconds with no service techs and no special tools compared to conventional casing connectors, which require two service techs and hand tools to install. The savings in time can equate to as much as $100,000 depending on rig rate and the number of casing strings.

Proven by testing, the Badger connector has the highest capacities, the lowest stress-amplification factor, and longest fatigue life in the industry. It features an innovative metal-to-metal, gas-tight seal to ensure reliable, environmentally responsible performance, Dril-Quip says.

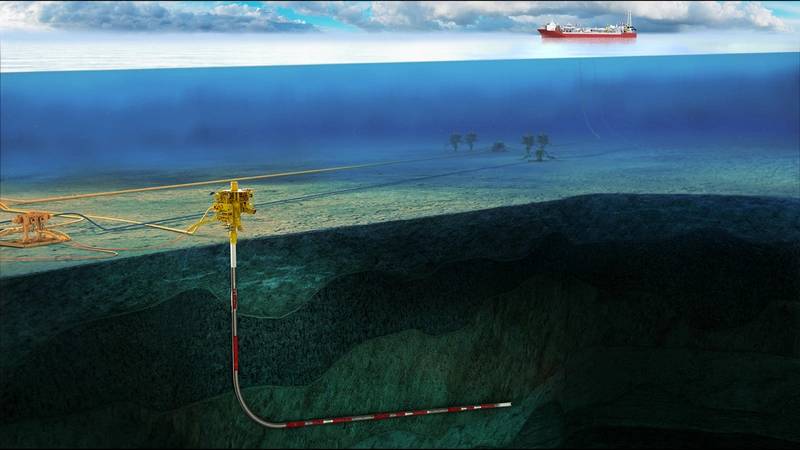

Halliburton and TechnipFMC, producer of Odassea Subsea Fiber Optic Solution Image courtesy HalliburtonThe Odassea Subsea Fiber Optic Solution integrates hardware and digital systems to strengthen capabilities in offshore reservoir monitoring and production optimization. Halliburton provides the fiber optic sensing technology and analysis for reservoir diagnostics. TechnipFMC provides the optical connectivity from the topside to the completions. Through this collaboration, operators can accelerate full-field subsea fiber optic sensing, design, and execution. ExxonMobil selected the Odassea solution for its Payara development project in Guyana. The award followed the completion of front-end engineering and design studies and qualifications. The Payara development, located 200 kilometers offshore Guyana in 1,800 meters water depth, is the third development within the Stabroek block with current discovered recoverable resources estimated at around 9 billion oil-equivalent barrels.

Image courtesy HalliburtonThe Odassea Subsea Fiber Optic Solution integrates hardware and digital systems to strengthen capabilities in offshore reservoir monitoring and production optimization. Halliburton provides the fiber optic sensing technology and analysis for reservoir diagnostics. TechnipFMC provides the optical connectivity from the topside to the completions. Through this collaboration, operators can accelerate full-field subsea fiber optic sensing, design, and execution. ExxonMobil selected the Odassea solution for its Payara development project in Guyana. The award followed the completion of front-end engineering and design studies and qualifications. The Payara development, located 200 kilometers offshore Guyana in 1,800 meters water depth, is the third development within the Stabroek block with current discovered recoverable resources estimated at around 9 billion oil-equivalent barrels.

TechnipFMC and Halliburton are delivering Odassea solutions to multiple other subsea projects at all stages, from conceptual design to execution.

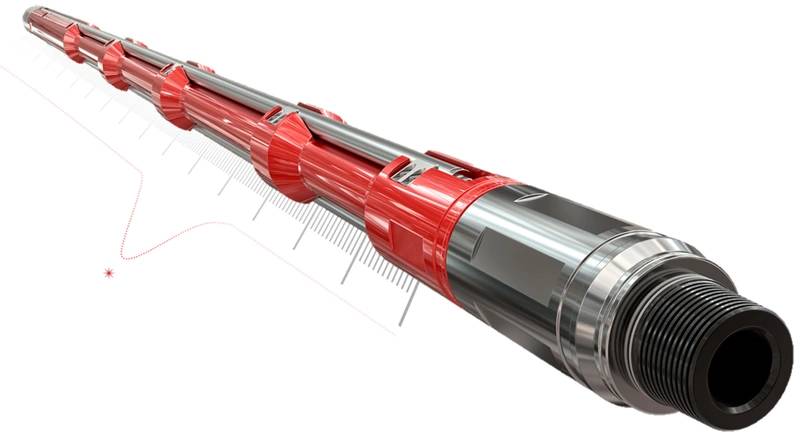

Halliburton, producer of DynaTrac™ Real-time Wireless Depth Correlation System Photo courtesy HalliburtonThe DynaTrac system enables operators to accurately position packers, perforating guns and the bottom-hole assembly (BHA) without running wireline or moving the work string. The system takes static measurements to determine the position of the BHA before and after setting the retrievable packer. Operators can measure depth at any time while tracking changes in position to improve operational efficiency. Through on-demand measurement of tool position, the technology reduces health, safety, and environmental risks associated with performing wireline operations.

Photo courtesy HalliburtonThe DynaTrac system enables operators to accurately position packers, perforating guns and the bottom-hole assembly (BHA) without running wireline or moving the work string. The system takes static measurements to determine the position of the BHA before and after setting the retrievable packer. Operators can measure depth at any time while tracking changes in position to improve operational efficiency. Through on-demand measurement of tool position, the technology reduces health, safety, and environmental risks associated with performing wireline operations.

Additionally, operators can configure the system to perform automatic position measurements to track BHA movement over time, which increases the accuracy and reliability of reservoir analysis. The technology reduces downhole uncertainty and improves reservoir insight while saving valuable rig-time.

Oil States Industries, producer of Merlin Deepsea Mineral Riser System Photo courtesy Oil States InsdustriesThe Merlin Deepsea Mineral Riser System is a robust, fast, hands-free riser system with remote monitoring that enables recovery of deepsea minerals used in electric vehicle batteries and supports the energy transition. Oil States with partners has become an integrator of complete mineral collection systems from harvester to vessel. In an industry first, the Merlin Deepsea Riser System was recently design-reviewed by ABS. The system is designed to collect polymetallic nodules 6,000 meters below the surface of the Pacific.

Photo courtesy Oil States InsdustriesThe Merlin Deepsea Mineral Riser System is a robust, fast, hands-free riser system with remote monitoring that enables recovery of deepsea minerals used in electric vehicle batteries and supports the energy transition. Oil States with partners has become an integrator of complete mineral collection systems from harvester to vessel. In an industry first, the Merlin Deepsea Riser System was recently design-reviewed by ABS. The system is designed to collect polymetallic nodules 6,000 meters below the surface of the Pacific.

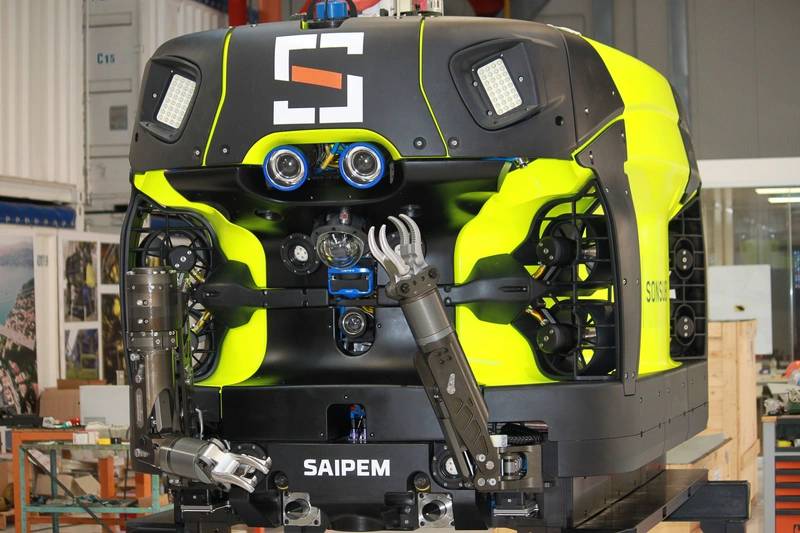

Saipem, producer of Hydrone-R Drone Photo courtesy SaipemHydrone–R is an Underwater Intervention Drone (UID), capable of performing both inspection and intervention missions and conceived to offer Life-of-Field Services focused on guaranteeing safety and productivity of Offshore Energy fields while minimizing operational costs. It is also the first-ever modular subsea resident intervention platform, integrated within the subsea field for dives up to 12 months. In 2019, Hydrone-R was chosen by Equinor to be the first UID commercially deployed in the Njord Field Development, offshore Norway, understood to be the first-ever worldwide service contract for subsea resident drones signed in the Offshore Energy Industry. The innovative value resides in:

Photo courtesy SaipemHydrone–R is an Underwater Intervention Drone (UID), capable of performing both inspection and intervention missions and conceived to offer Life-of-Field Services focused on guaranteeing safety and productivity of Offshore Energy fields while minimizing operational costs. It is also the first-ever modular subsea resident intervention platform, integrated within the subsea field for dives up to 12 months. In 2019, Hydrone-R was chosen by Equinor to be the first UID commercially deployed in the Njord Field Development, offshore Norway, understood to be the first-ever worldwide service contract for subsea resident drones signed in the Offshore Energy Industry. The innovative value resides in:

Schlumberger, producer of DrillPlan coherent well construction planning solution Image courtesy SchlumbergerSchlumberger's DrillPlan coherent well construction planning solution is a cloud-based application that accelerates the delivery of an efficient and optimal drilling program. The solution provides a digital collaborative space that enables the discovery and consumption of offset knowledge and cross-domain engineering workflows in one place. Data is liberated from siloed repositories to enrich the context of data-driven insights to achieve continuous improvement.

Image courtesy SchlumbergerSchlumberger's DrillPlan coherent well construction planning solution is a cloud-based application that accelerates the delivery of an efficient and optimal drilling program. The solution provides a digital collaborative space that enables the discovery and consumption of offset knowledge and cross-domain engineering workflows in one place. Data is liberated from siloed repositories to enrich the context of data-driven insights to achieve continuous improvement.

Automated design and validation workflows accelerate the delivery of an efficient and optimal drilling program with a few clicks. The solution can also be connected to vendor-neutral databases or applications, using application program interfaces (APIs) and open-source code, to create bespoke solutions that help operators achieve greater levels of flexibility, automation, innovation and high-powered computation.

Since 2019, the DrillPlan solution has helped operators, including several NOCs and IOCs, plan more than 7,000 wells.

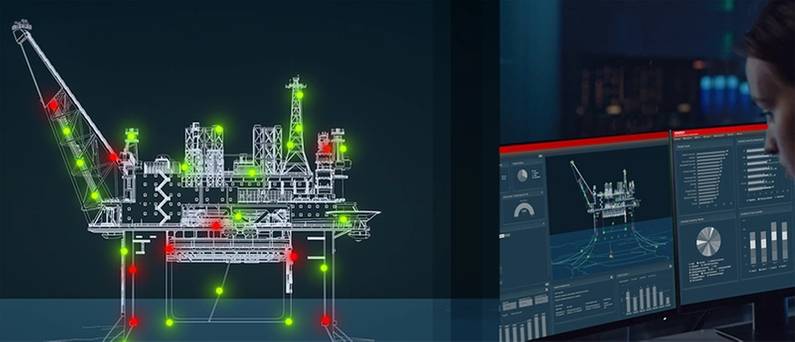

Siemens Energy, producer of APM4O&G and MyFleetRisk Image courtesy SiemensSiemens Energy won two awards for APM4O&G and MyFleetRisk solutions.APM4O&G delivers a diagnostic and decision-support solution for oil and gas equipment, enabling a step-change in how offshore operators manage their assets. By continuously comparing real-time equipment operational data against models and running automated diagnostics, operators can forecast performance, pre-empt failures, and conduct reliability-centered maintenance.

Image courtesy SiemensSiemens Energy won two awards for APM4O&G and MyFleetRisk solutions.APM4O&G delivers a diagnostic and decision-support solution for oil and gas equipment, enabling a step-change in how offshore operators manage their assets. By continuously comparing real-time equipment operational data against models and running automated diagnostics, operators can forecast performance, pre-empt failures, and conduct reliability-centered maintenance.

MyFleetRisk is a data-driven, collaborative risk management platform that leverages real-world engineering expertise to quantify and visualize risk profiles of Siemens Energy's oil and gas customers' gas turbine fleets. Its transparent delivery of risk and criticality information empowers offshore operators with actionable insights without the need for connectivity in a challenging environment.

Subsea 7 and autonomous Subsea 7 subsidiary Xodus Group, producer of Subsea 7 NESP – Nano Engineered Sensor Platform Image courtesy Subsea 7Subsea 7 Nano Engineered Sensor Platform (Subsea 7 NESP), developed in collaboration with Xodus, is a transformative solution that can continuously monitor fatigue and corrosion offshore, reducing OPEX in these areas. The wireless nano-technology sensor can be deployed efficiently and easily across any operating asset. Subsea 7 NESP, which requires no power supply or batteries, offers a scalable, cost-effective, zero maintenance solution to extend asset life and improve uptime.

Image courtesy Subsea 7Subsea 7 Nano Engineered Sensor Platform (Subsea 7 NESP), developed in collaboration with Xodus, is a transformative solution that can continuously monitor fatigue and corrosion offshore, reducing OPEX in these areas. The wireless nano-technology sensor can be deployed efficiently and easily across any operating asset. Subsea 7 NESP, which requires no power supply or batteries, offers a scalable, cost-effective, zero maintenance solution to extend asset life and improve uptime.

The NESP technology fully integrates with Xodus' Asset Management & Integrity Network (XAMIN) tool, which allows the company's experts, infrastructure owners and operators to capture design, installation, testing, operating, inspection, and decommissioning information within a single system. This additional capability leads to a further increase in efficiency, ensures regulatory compliance, and helps optimize the performance of assets.

Below are the winners of the OTC 2021 Spotlight Small Business Awards. Find more about these awards on the OTC website https://2021.otcnet.org/: