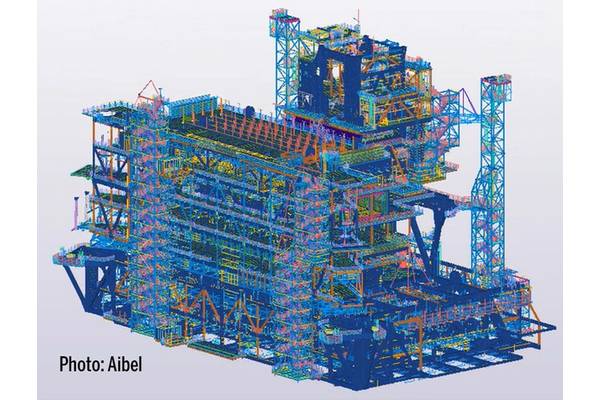

The design and construction of offshore oil and gas platforms are both complex and unique, requiring incredible precision and close collaboration between all parties. For this reason, 3D models play an important role in the lifecycle of offshore oil platforms.

Norwegian offshore constructor Aibel has put 3D models at the heart of its work designing and manufacturing oil platforms.

Founded more than 130 years ago, Aibel serves the global energy industry with engineering, construction, and maintenance services. The company employs 4,000 people at engineering offices and yards in Norway, Singapore, and Thailand, and to date, has built or modified more than 50 platforms.

In 2013, Aibel set a goal to reduce overall engineering time by up to 30 percent. To meet its target, the company began looking closely at how construction documentation is produced and the ways in which teams working in different locations collaborate and share information.

Through this process, Aibel discovered constructible BIM and its ability to help the company create 3D models with data so accurate it translates directly to the physical world. As it embarked on several projects for the Johan Sverdrup offshore oil field, finding the right solution that would allow Aibel to create constructible models and efficiently extract fabrication information from them, as well as collaborate across teams in multiple locations would allow the company to design and construct offshore platforms with greater efficiency and accuracy.

"Our colleagues in Singapore and Thailand were already using Trimble's BIM software Tekla Structures for the high-value engineering work we do in Southeast Asia," said Charles Halaas, IT manager of field development and offshore wind for Aibel. "When we saw how efficient their output is and the tremendous volume of documentation they are able to produce, we set up a team to see how we could use it in other projects too."

Uncovering Efficient Design and Automating Production

The project was not without its challenges due to standardization requirements within the oil and gas industry and the need to integrate Aibel's BIM software with existing solutions.

"The design model and the fabrication model should always be the same, but as our industry requires the use of E3D as a design tool, it is challenging to extract a 3D fabrication model into the BIM software," said Halaas. "Thanks to some great cooperation with experts, we were able to produce interface methodology to overcome this challenge and semi-automate our drawing production."

Introducing constructible BIM into the fabrication process is instrumental in helping Aibel with robotics, another of the company's focus areas for development. Aibel uses state-of-the-art computer-controlled cutting machines in its yards and, through integration with its BIM software, has achieved a higher degree of automation across the design and manufacturing process.

"We see the greatest benefit of this integration in our profile-cutting machines," said Halaas. "For example, when we have two metal beams meeting at a given point, there is usually a crossover joint that is quite complicated to cut. Previously, we used manually operated mechanical saws to cut these. Now we use the Tekla model to guide the robot and cut with incredible accuracy."

Building Some of the Industry's Largest Oil Platforms

The efficiencies achieved with constructible 3D models are critical for Aibel as the company builds some of the industry's largest oil platforms in the Johan Sverdrup oilfield.

The Johan Sverdrup oilfield's location made its discovery in 2010 somewhat of a surprise. In the area of the North Sea where the field is situated, oil exploration began in the late 1960s.

It was long thought that the area was exhausted of oil, which couldn't have been farther from the truth.

As one of the largest oil fields in Norway's history, production in Johan Sverdrup will continue until at least 2050 and yield an estimated 2.7 billion barrels.

In 2018, Aibel was awarded a contract for the engineering, procurement, and construction of the Johan Sverdrup Process Platform II, the company's largest project to date, weighing approximately 25,000 tons and requiring more than 17,000 structural drawings.

"We are very much into digital fabrication at our operations in Norway and Thailand," said Halaas. "At Aibel, we want to go all the way and develop 3D models that are ready for machinery and fabrication. This is our vision of a digital yard. If we do not go in the digital direction, then we risk losing future projects by not being competitive enough. Fabrication-ready 3D models are a very efficient way of working. In addition to efficiency gains, the improved robotics have made our yards safer, as there is less need for employees to lift and cut heavy materials."

Getting Buy-In Across the Company

To ensure employees at all levels of the organization were behind its adoption of 3D modeling and new collaboration process, Aibel used a pilot-project approach and enlisted the help of key internal influencers.

"This has been a giant leap for us that demanded trust, commitment, and hard work from people across Aibel's operations," said Halaas. "The result is that we are now more seamless in distributing and sharing work around the world, as Tekla Model Sharing makes collaboration much easier. We can now appoint anyone anywhere in the world to create drawings for us."

Aibel typically does design work in Norway and then extracts the drawings for fabrication in Thailand and Singapore. "This global way-of-working has been much more challenging in previous projects, when we were not able to share 3D models in the cloud," said Halaas. "In the past, we had to freeze the work more often. Now we can work much more flexibly."

Breaking Barriers with Data-Rich Models and Global Collaboration

Constructible 3D models and collaboration will continue to play a very important role in Aibel's future. The P2 project exceeded its digitalization ambitions to reduce interfaces, automate drawing production and increase efficiency and robustness for the project execution," said Ståle Nordal, project director, Johan Sverdrup P2 Topside, Equinor. "Tekla is one of the initiatives that increased quality and reduced drawing production time for P2 and will provide a positive impact for future projects."

Less than a year after the Platform II contract was awarded, the first construction activities began at Aibel's yard in Laem Chabang and also at its subcontractor Deeline in Rayong, Thailand. Two years later, the module was completed and comprised four decks with a perimeter equivalent to a football field and a total weight of approximately 14,500 tons. Overall, this makes it the largest platform module ever built on Thai soil – beating the previous record held by the Johan Sverdrup Drilling Platform Main Support Frame, which was also built by Aibel Thailand.

This giant module will be transported to Aibel's yard in Haugesund, Norway, by the vessel GPO Sapphire. Arriving in Norway, it will be connected with the two remaining modules, UPM and HVDC, creating one platform for the Johan Sverdrup oil field. This spectacular lifting operation will be performed by the world's largest crane vessel, Sleipnir. The complete platform is scheduled for final delivery to client Equinor in early 2022.