Reimagining uses for innovative technologies originally designed for critical service in subsea developments could open the door to safer CO2 storage and usage.

The energy transition occurring worldwide is redefining energy production and consumption and consumer perceptions of the oil and gas industry. Today, many consumers want a more sustainable method of energy generation in line with global pledges on climate emissions and control, and financial institutions are increasingly basing investment decisions on Environmental, Social, and Governance (ESG) performance. This new focus has led to wide-ranging programs with the common goal of finding economical ways to decarbonize industrial zones.

Improving carbon capture, transportation, utilization, and storage is a critical step on the road to reducing the greenhouse gas (GHG) emissions produced by these large industrial emitters. And, CO2 abatement is essential to achieving carbon reduction commitments for the foreseeable future.

As new methods of energy generation are introduced to industrial zones to reach decarbonization targets, more efficient ways must be found to transport CO2 away from these areas to underground storage. While there is broad agreement that change is necessary, the way forward is unclear. Lowering the carbon footprint of industrial operations without negatively impacting quality of life will be a challenge.

Dril-Quip is proactively addressing this issue with creative problem-solving, developing solutions that will reduce GHGs and enable safe and reliable carbon capture, transportation, utilization, and storage. The company officially pledged to be a part of the broader solution by becoming a participant in the United Nations Global Compact (UNGC), the world’s largest sustainability initiative, in early 2021. The UNGC aligns companies to support its universal principles on human rights, labor, environment, and anti-corruption.

New applications for proven technologies

Exceptional engineering delivers solutions that reduce the time, cost, and risk involved in complex processes. Developing these innovations, however, is anything but simple. It requires the ability to consider challenges from a different point of view and use that perspective to create designs that resolve issues in a novel way.

Dril-Quip used this approach to develop its e-Series products ─ solutions that fundamentally change some of the ‘norms’ for the oil and gas industry. The company has staked its reputation on these new concepts. And now, building on years of experience and success, including the recent installation of several ‘serial number one’ solutions, it is introducing game-changing technologies for CO2 transportation and storage.

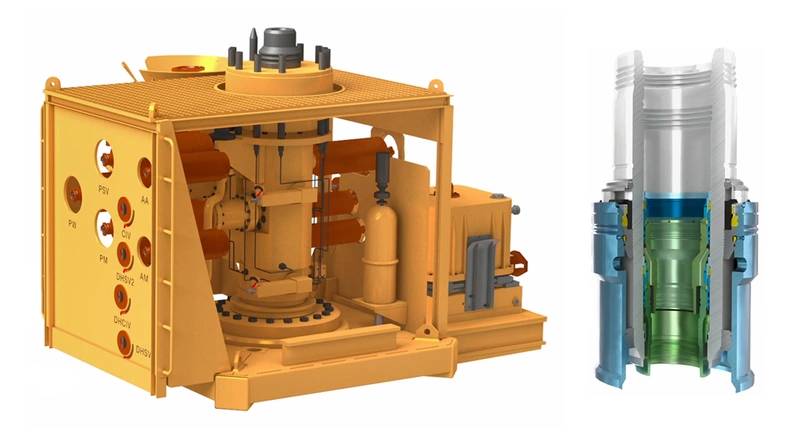

Dril-Quip leveraged its best-in-class wellhead technology and tree innovations to develop a lightweight, compact, and economical solution for long-term carbon storage and injection applications. (Image courtesy of Dril-Quip)

Dril-Quip leveraged its best-in-class wellhead technology and tree innovations to develop a lightweight, compact, and economical solution for long-term carbon storage and injection applications. (Image courtesy of Dril-Quip)

Transitioning innovations for CCUS applications

One of the products Dril-Quip has introduced for carbon capture, utilization, and storage (CCUS) applications is the lightweight, compact Dril-Quip® SingleBore™ Vertical Tree System or SBTe™. Based on Dril-Quip’s field-proven, shallow-water tree, the SBTe can be configured for CO2 service and incorporates a self-aligning feature that simplifies tree installation.

The SBTe, which is designed to handle the harsh conditions associated with CO2, is fit for purpose for CCUS applications. Dril-Quip’s in-house metallurgists specified material that is lighter than other commonly used solutions and applied their cladding expertise to ensure reliable performance even in the harshest subsea injection conditions. Recognizing that the purity of the CO2 could become an issue over time as carbon emitters make plans to capture increasing volumes of CO2 from industrial operations, the tree can manage CO2 impurity levels as low as 92%. Rated for 5,000 psi maximum pressure and temperatures as low as -46ºC (-50ºF), the tree is available as a hydraulically powered or fully electric solution. The electric version provides enhanced long-distance power distribution and management and enables faster data transfer/communications for optimal digital monitoring.

Automatic space-out adjustment enables the tubing hanger to self-adjust to variances in the hanger’s position. The stab subassembly allows the tubing hanger to be precisely aligned and installed like a casing hanger without the need for a lead impression trip. When the tubing hanger is landed, a pressure test verifies the hanger is in the correct position. Then, a hanger lock mandrel is placed with a tubing hanger running tool, creating a flat lock mandrel-to-lock ring interface. Its coupler body houses 13 hydraulic and two electrical coupler lines that rotate +/- 180 degrees to connect to corresponding couplers in the tubing hanger. Drilling and completion can be carried out without suspending the well or pulling the BOP stack.

Coupled with Dril-Quip’s best-in-class wellhead technology, the agnostic SBTe design can be an integral component of any comprehensive storage and injection infrastructure. It can be incorporated into a template attached to either a pipeline or marine buoy for CO2 injection and easily connects to flexible risers and monitoring equipment.

The ability to step back and examine existing technologies and envision something different is a core capability that gives Dril-Quip advantages in developing CCUS solutions. The SBTe system design reduces hardware and significant operational steps and as a result, lowers the carbon footprint. It is a clear example of looking at installation challenges from a different perspective and using mechanical engineering ingenuity to introduce a unique product.

Synergies in collaboration

While Dril-Quip is working independently to develop technologies to advance CCUS initiatives, it also is collaborating with companies that complement its strengths and capabilities.

One such partnership was formalized in late February 2022 as a Collaboration Agreement with Aker Solutions. Within this agreement, Dril-Quip will provide CO2 injection trees and wellheads incorporating Aker’s proprietary control systems and electrification components. The partners will cooperatively target opportunities where they can add significant value, specifically in the North Sea where the industry is leading the charge with respect to active CCUS projects.

Dril-Quip is pursuing additional partnerships, including one focused on marine shipments of CO2. The company is actively working with onshore and marine logistics companies as well as storage development organizations to develop a ‘shore-to-seabed’ methodology that will allow industrial zones to load, transport, inject, and store CO2 in a manner that is cost-effective, safe, and reliable and that also reduces operational carbon emissions.

The path forward

As governments implement carbon taxes around the globe, the economic benefit of storing CO2 must be realized, and technology will pave the way. Dril-Quip is committed to being part of the solution by providing innovative, economical solutions to help the industry achieve its CO2 injection and storage goals.

About the Author

Dril-Quip Director of Energy Transition John Mossop joined the company in 2020 and has more than 20 years’ experience in engineering/management.