Hydrogen has been making big headlines in the energy world. It’s one of the potential routes to deliver high density energy to transport and heavy industry – but also to marine applications, as well as a way to move and store renewable energy. Various uncrewed surface vessel (USV) developers, autonomous underwater vehicle (AUV) builders and even subsea power delivery system providers are taking a serious look – and even trialing – hydrogen as an option.

SEA-KIT

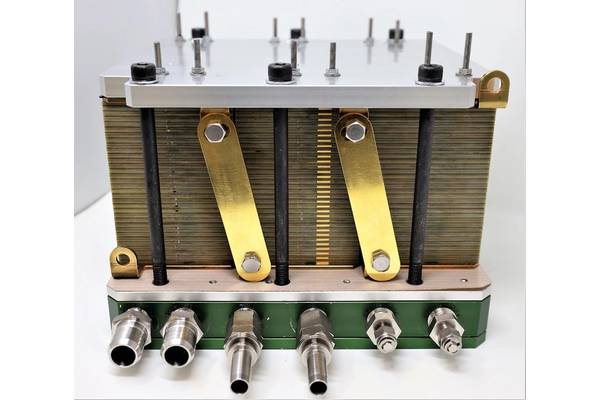

The Maxlimer hydrogen configuration. Image courtesy SEA-KIT International

The Maxlimer hydrogen configuration. Image courtesy SEA-KIT International

Two UK firms, SEA-KIT and ACUA Ocean are working on hydrogen power systems for their USVs. SEA-KIT, through the Clean Maritime Demonstration Competition funded by the UK’s Department for Transport (DfT), is working on installing a PCB (printed circuit board) based hydrogen fuel cell, engineered by Bramble Energy, on its 12 m-long demonstration vessel Maxlimer USV. It’s aiming for a demonstration by the end of the year, says Commercial Manager David Ball.

Currently, SEA-KIT USVs have a dual diesel-electric hybrid drive, with propulsion coming from an electric motor powered by battery banks that are charged by in-situ diesel generators. This project will replace one of the diesel generators with new hydrogen fuel cell technology and demonstrate an offshore operation with zero carbon emissions.

Bramble Energy, also based in the UK, is designing a marinized, customized version of its PCB fuel cell. The use of PCBs, as opposed to metallic or graphite end plates, makes the technology more suited to rugged, marine environments, says the firm. Bramble Energy’s PCBFC system will sit inside an enclosure within the USV to prevent sea water ingress and corrosion.

The build is nearing completion at a newly built test facility at Bramble Energy. After successful bench testing and verification society inspection, it will be installed into the USV.

SEA-KIT says data from the bench testing and sea trials will be used for the design and build of similar USVs, as well as for larger uncrewed vessel builds.

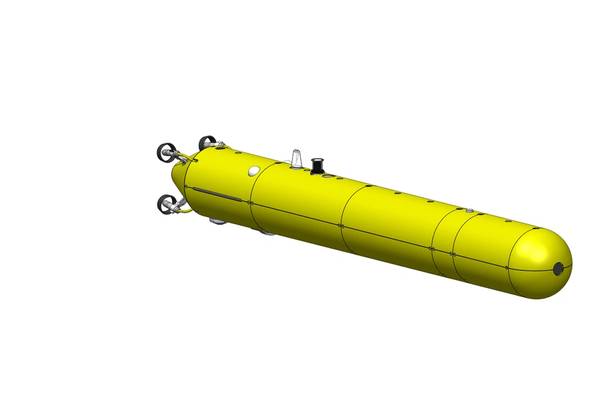

ACUA Ocean ACUA Ocean’s H-USV. Image courtesy ACUA Ocean

ACUA Ocean’s H-USV. Image courtesy ACUA Ocean

ACUA Ocean has received DfT funding through Innovate UK to build a hydrogen powered USV (H-USV) for long endurance operations, as part of swarm operations at sea.

It completed work on the subsystems and has plans to launch a prototype to be named Ocean Protector and perform site acceptance testing in 2023, followed by swarm demonstrations in 2024 and swarm deployments in 2025. The vessel is being developed in collaboration with local naval architecture firm Ad Hoc Marine Designs and features a small waterplane area twin hull for stability (SWATH).

ACUA Ocean is targeting up to 60-day deployments while operating at four knots, though it says a peak speed of 18 knots can be achieved for monitoring and interceptions, using liquid hydrogen fuel capacity of 6,000 litres.

The ACUA Ocean design has received approval in principle (AIP) from classification society Lloyd’s Register for its hydrogen system, its control engineering system, and its electrical power distribution systems, following the factory acceptance testing of the prototype systems undertaken in March this year.

The prototype is being built by a consortium of UK shipbuilders, with shipfitting and electrical outfitting contracts being awarded to Lowestoft-based firms SMS and Trident Marine Electrical, while the hydrogen fuel cell is being developed by Proton Motors.

The vessel’s name commemorates the Tyne pilot cutter, the Protector, which was sunk after hitting a German sea mine during World War I, with the loss of all nineteen crew members, including William Hopper Tinmouth, the great great grandfather of the founders of ACUA Ocean.

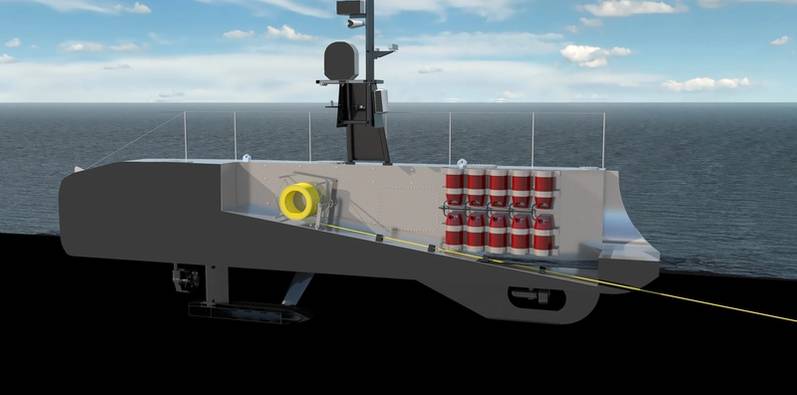

ENDURUNS The ENDURUNS USV, en-route to Cyprus. Image courtesy ENDURUNS

The ENDURUNS USV, en-route to Cyprus. Image courtesy ENDURUNS

Over in Europe, combining hydrogen powered, long-endurance AUVs with hydrogen powered support USVs is the goal of the collaborative ENDURUNS project.

The consortium includes space, defense, marine and drone technology companies, universities, institutions, consultancies, a certification body and a port from Greece, the UK, Korea, Denmark, Italy, Spain, Switzerland, Lithuania, Belgium and Cyprus.

Their goal is a 5.5m-long, hydrogen fuel cell powered hybrid AUV, with a Li-ion battery for supplementary power, in case of failure or emergency, and energy management for the propulsion system and sensors.

It will be partnered with a USV that will follow the AUV at the surface to transmit data from the AUV to onshore, also allowing for mission parameters to be changed. According to the ENDURUNS website, it will also retrieve data “from data bubbles” (pencil-like capsules containing SD cards) that can be ejected from the AUV when needed or in an emergency.

The prototype AUV, being developed at Graal Tech in Italy, with completion expected by Q1, 2023, is planned to have a glider mode, to conserve energy, using propelled mode when performing seabed surveys or inspection tasks.

The 8m-long prototype USV will be electrically powered using a combination of hydrogen PEM fuel cell, Li-ion battery and thin film solar cells. It will provide the required high-resolution geotagging data, mission maps and mission locations and will be able to dock and recharge the AUV’s battery when its hydrogen has been exhausted.

This summer, the USV left the shipyard of Tuco Marine - ProZero Workboats in Denmark and arrived in Chania, Crete. There, it will have its systems, including instrumentation and the hydrogen PEM fuel cell, integrated, followed by testing over winter.

Cellula Robotics

The mini AUV shown as it would be launched from the Solus LR underwater.

The mini AUV shown as it would be launched from the Solus LR underwater.

Developing a hydrogen powered AUV has also been a goal for Canada’s Cellula Robotics – and this summer it got its system into the water. Its goal is to get to 2,000 km endurance with its hydrogen fuel cell powered Solus-LR vehicle. Cellula’s SeaWolf project, with the Australian navy (also called Solus XR), is even bigger (12m-long) and with more oxygen and hydrogen, and targeting 5,000km.

Earlier this year, the company performed its first endurance pool tests on its fuel cell. It ran for more than three days without any issues. Then, in July, it took its 8.5m-long Solus-LR vehicle, complete with integrated fuel cell capable of carrying 250 kWhr of energy, out for at-sea testing.

This involved two and a half weeks of testing in Vancouver’s Indian Arm Inlet, including trailing deployment of two, 70cm-long (including antenna) micro-AUVs from the Solus-LR while submerged and underway, all powered by the fuel cell.

As fuel cells prefer steady state running, cycling between on and off and running hard was quite a stress test, says Alex Johnson, AUV Product Manager at Cellula. “It was very exciting and almost to the point where we didn’t have to think about it anymore – it was just something that worked.”

Cellula was then due to run a 24-hour endurance test, covering 130 km, in September (after going to press).

Teledyne Energy Systems

Teledyne’s Subsea Supercharger with Innova subsea hydraulic pumping unit, developed by Innova. Photo from Teledyne.

Teledyne’s Subsea Supercharger with Innova subsea hydraulic pumping unit, developed by Innova. Photo from Teledyne.

To support underwater vehicle repowering, Teledyne Energy Systems has been developing a seabed Subsea Supercharger, based on PEM fuel cell technology. It’s set to test this system with an AUV later this year.

The Subsea Supercharger system comprises of a fuel cell stack, product water management and the reactant (hydrogen and oxygen) supply. The system is configurable for more than 3 MWh of energy capacity, says Teledyne, and is designed to be deployed down to 1,000m water depth and provide up to 8 kW of steady state power.

Earlier this year, it worked with Innova to put its Subsea Supercharger through validation testing at the Norwegian Center for Offshore Education, Tau Autonomy Center a subsea testing facility not far from Stavanger, Norway.

The validation tests in Tau included putting the system to use powering a subsea hydraulic pumping unit developed by Innova. “The two systems were integrated and successfully deployed to a depth of 235 m (770 ft) where subsea control fluid was pumped to a pressure of 180 bar (2,600 psi) for 30 minutes, six times a day,” says Teledyne. “During the test, the Subsea Supercharger seamlessly transitioned from ‘Sleep-mode’ to ‘On’, in response to power demands from the pumping unit as it repeatedly cycled on and off,” says Teledyne.

Teledyne Energy Systems said it’s now planning a demo that will involve an AUV on a scientific mission in the Great Lakes region, in North America, docking with its Subsea Supercharger. This exercise will occur around November of 2022 and recharge the vehicle which will then be redeployed.

Lhyfe

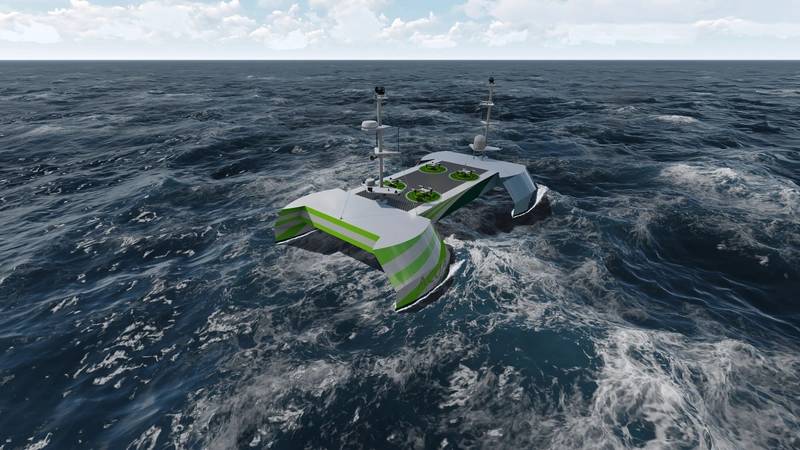

Image courtesy Lhyfe

Image courtesy Lhyfe

Finally, it’s ok supplying hydrogen to these fuel cells. But where does the hydrogen itself come from? French firm Lhyfe has developed a neat combination, using wave energy and electrolysis to produce renewable hydrogen offshore. It installed an electrolyzer on a hybrid renewable energy platform from GEPS Techno that was launched in late September at the SEM-REV demo site offshore Saint-Nazaire, France. It’s looking to scale up, working with Chantiers de l’Atlantique to develop minimum 100MW capacity that could work alongside existing fixed or floating structures.