BladeBUG, a UK-based robotics company which designs and develops spider-like repair robots for the wind industry, has has announced collaboration with non-destructive testing (NDT) specialist, FORCE Technology.

The joint project will see FORCE Technology produce custom NDT solutions for integration within BladeBUG's innovative crawler robot, which is specifically designed to maintain and inspect wind turbine blades.

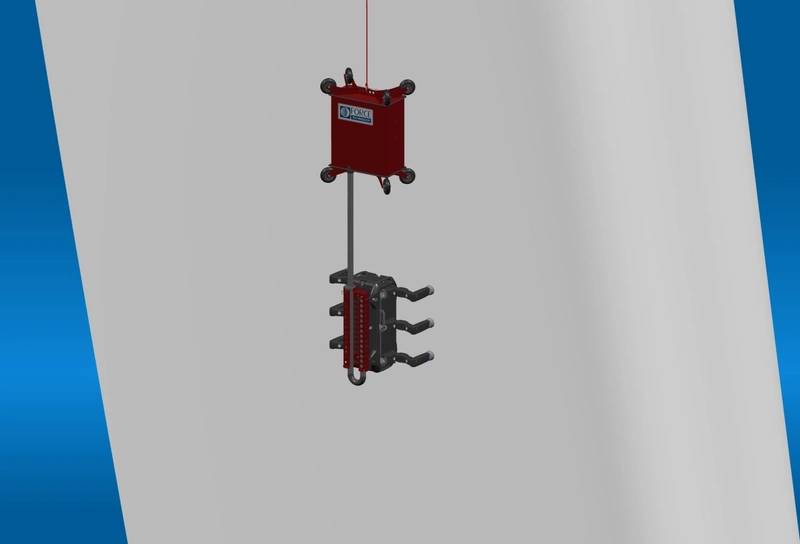

FORCE Technology is providing its P-scan ultrasonic composite scanning system, combined with BladeBUG's six-legged crawler robot, "to enable a ground-breaking solution for remotely operated scanning of wind turbine blades, both on- and offshore."

The collaboration between BladeBUG and FORCE Technology will introduce a portable and efficient solution for up-tower in-service non-destructive testing of wind turbine blades, BladeBUG said. Credit: BladeBUG

Credit: BladeBUG

BladeBUG says that, with the integration of FORCE Technology's automated ultrasonic scanning system, BladeBUG's crawler robot will be able to perform thorough inspections of critical structural parts, including spar caps, root areas, leading edges, trailing edges, and more. This advanced scanning capability ensures comprehensive detection of all relevant defect and damage types, such as wrinkles, debonding, delamination, and others, regardless of the blade's curvature, BladeBUG said.

"One of the key advantages of this collaboration is the cost efficiency it offers. The deployment process is streamlined, allowing for fast and efficient inspections," the company said.

Chris Cieslak, Founder and Director at BladeBUG, explains, “BladeBUG’s joint solution with FORCE Technology is set to empower wind industry stakeholders with advanced inspection capabilities that enhance asset management, ensuring the integrity and longevity of wind turbine blades. Combining the maneuverability, accuracy, and adaptability of BladeBUG’s crawler, with the reliable, trusted technology within FORCE Technology’s custom-built NDT solution will help revolutionize O&M activities in the wind industry.” Credit: BladeBUG

Credit: BladeBUG

BladeBUG says that the intelligent scanning technology integrated into BladeBUG's advanced robot, combined with AI-based data analysis, also enables quick and accurate results.

"This means wind industry stakeholders can obtain a fully documented overview of the structural condition of their assets in a timely and cost-effective manner. Whether it is at the time of delivery, before the end of warranty, during a change of ownership, or when considering lifetime extension, this joint solution provides valuable insights for decision-making," BladeBUG said.

Lars Vesth, Chief Operating Officer at FORCE Technology said: "FORCE Technology is pleased to work with BladeBUG to offer this unique solution for remotely operated scanning of wind turbine blades, both on- and offshore. Due to the rapid ramping up of production in the industry, and the unprecedented scaling up of components seen in the last few years, new and efficient structural inspection concepts are needed.”