Matt Hart, Manager & Platform Leader, Marine & Stationary Power Systems, Wabtec, offers insights on how the megatrends of decarbonization, energy transition and autonomy all inspire and impact the marine power solutions from Wabtec.

I graduated from the University of Notre Dame with an undergraduate in Mechanical Engineering and started with General Electric in the Edison Engineering Development rotational program at the Erie, PA, site, primarily focused on the development and release of the new Tier 4 locomotive. Following that, I focused my interest into the area of engine performance calibration, emissions and combustion research through a ME master’s degree at Georgia Tech and through experience at GE with development programs for our Tier 4 Rail and FDL Locomotive Modernization programs.

From there, I decided to go back to school and get my MBA from Gannon University here in Erie. Leveraging that growth opportunity, I moved into Wabtec’s Engine Platforms Team, leading key reliability cases and maritime programs; which led me to the current role I have now as the Marine & Stationary Platform Leader, responsible for the product development and install base support across our full Engine Technology organization, as well as leading our Marine & Stationary Systems team.

Wabtec is a Fortune 500 company based in Pittsburgh, PA with about a $8-9B revenue. We are based in more than 50 countries, with more than 27,000 employees, and we have more than 50 years of engine manufacturing experience, with more than 30,000 engines produced across all applications. The maritime business is a group within our Freight Equipment business, with more than 1,000 engines in service or commissioning, primarily powering customers in the work boat sectors, including dredging, river tugs, harbor tugs, ATBs, ferries, and medium-size cruise ships.

“Wabtec achieved Tier 4 NOx and PM without the use of aftertreatment, which sets our product apart from the competition in unlocking logistical flexibility and life-cycle cost savings for the owner.”

“Wabtec achieved Tier 4 NOx and PM without the use of aftertreatment, which sets our product apart from the competition in unlocking logistical flexibility and life-cycle cost savings for the owner.”

Matthew Hart, Manager & Platform Leader, Marine & Stationary Power Systems, Wabtec

Photo Carly Masiroff

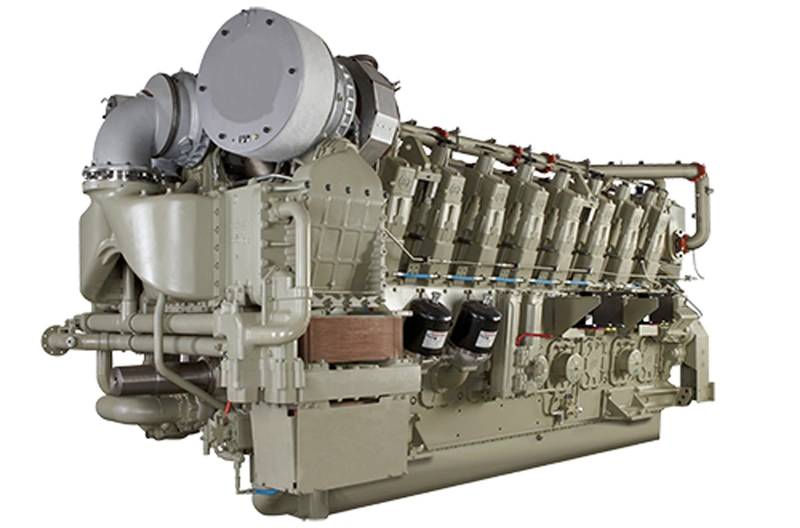

Wabtec’s first marine engine product was introduced back in the late 1960’s for Lower Lakes Towing and was primarily the rail V228 engine, or FDL as it is known in the rail industry. Fast forward to the 1990s and 2000s, Wabtec was now offering a marinized version of the V228 product from 8 to 16 cylinders. That engine is called the V228 for the bore size in millimeters.

With the advent of emissions regulations for EPA and IMO, Wabtec developed a marinized version of its Evolution-series Engine, known as the 250MDA & MDB products. When EPA Tier 4 and IMO Tier III were introduced in 2015/2016, Wabtec again offered a marinized version of its Tier 4 solution. Wabtec achieved Tier 4 NOx and PM without the use of aftertreatment, which sets our product apart from the competition in unlocking logistical flexibility and life-cycle cost savings for the owner.

First and foremost is the design robustness. When we talk about the rail application, one of the things that come to mind is tunnel performance, extreme environment performance, as well as long maintenance cycles. Serving our customers through improved lifecycle cost, trade-offs, it also allows us to do concurrent design and reliability demonstrations. We’re able to learn across both applications to make them better where one application might be more extreme from another, so we can take the most robust design proven in all applications and apply it in the best manner possible. The biggest piece for Tier 4, when we were developing that in the rail industry, was a heavy push away from the use of urea because of the logistics and the infrastructure that would be needed. That really helped prop up the unique marine solution.

Image courtesy Wabtec

Image courtesy Wabtec

Wabtec is committed to offering alternative fuel solutions across it’s inline and V-configured 250mm bore diameter engine families. The L/V250 engine family has more than a decade of dual fuel operation with diesel fuel and LNG. Biofuel blends up to 100% are in operation today, running on both biodiesel and renewable diesel blends. Wabtec also is investing in low carbon fuel technologies through its’ alternative fuels programs that includes the use of hydrogen, methanol, and ammonia fuel. The L/V250 engines are designed with the features, like 250bar firing pressure capability, that allow for minimally invasive engine adaptations (top deck and fuel system) of the engine when transitioning to low carbon fuels if and when our customers operations support the introduction of such fuels. One example of this is the single cylinder and combustion modeling research and development we are conducting with Oak Ridge National Lab and Argonne National Lab.

One of the big components is going to be the cylinder head based on the requirements of a customer for multi fuel use. The substitution ratios they require is going to determine what kind of fuel injection system is used – port, low or medium pressure fuel injection, high pressure direct injection – that’s going to dramatically change the fuel injection technology, and the cylinder head design could include multiple injectors.

Another big one is, depending on the injection technology and like we talk about hydrogen with high pressure, is driving towards a cryo fuel pump, which is something that does not exist in service. It is being invented by a number of companies, so that’s another key area that we’re investigating.

Absolutely. It is something that we’re taking to heart readily, designing for long maintenance intervals to make sure that our engines don’t have to be touched from a maintenance perspective to allow longer unmanned operation. In 2022 we released a new technology to our engine, an automated blow-down strategy to allow an unmanned engine room.

The ever-changing regulatory landscape on fuels and making sure that we are ready when the “green-fuel” supply chain catches up to the desire to transition.

Watch the full video interview with Matt Hart on Maritime Reporter TV: