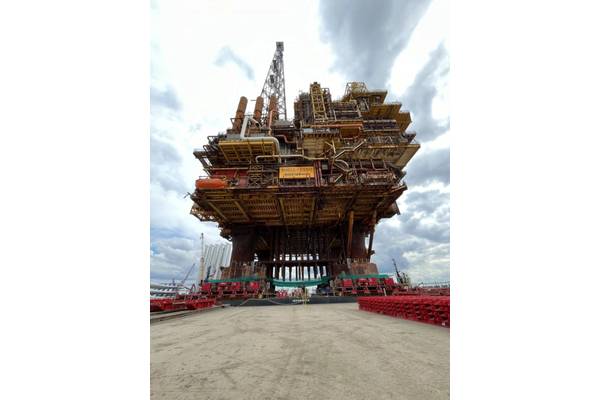

Mammoet has completed the load-in of the last and heaviest of the Brent oil and gas field topsides, Brent Charlie, which has been skidded onto the quayside for decommissioning operation.

The Brent field, one of the largest oil and gas fields in the North Sea, was a Shell-operated field located 186km northeast of the Shetland Islands.

It was once home to four oil and gas platforms - one jacket-based (Alpha) and three gravity-based (Bravo, Charlie and Delta).

Brent Delta ended production in 2011, Alpha and Bravo in 2014, leaving Charlie as the final one in operation.

Mammoet has performed the decommissioning load-ins of all three gravity-based topsides, with Brent Charlie the last and the heaviest.

Performing skidding of the 31,000t topside onto the quayside, whose concrete legs were submerged in seawater for over 40 years, required careful engineering to ensure the stability needed to carry out this operation safely and with precise control.

The steps to remove and transport the Charlie topside from the Brent field to the Able Seaton Port near Hartlepool in UK for decommissioning were largely unchanged from the previous three Brent topsides.

Allseas used its motion compensated heavy lift vessel Pioneering Spirit to remove the structure at sea in a single lift and transport it to shallow waters, where the topside was transferred onto Iron Lady, Allseas’ purpose-built cargo barge.

Mammoet had already fitted Iron Lady with skidding equipment, which would be needed to offload Brent Charlie at the port.

Mammoet also provided mooring winches for Iron Lady within specific guidelines provided by Allseas on lengths and drum load capacities.

Once the barge had moored at Able Seaton Port and settled into the seabed, the team could determine the starting height of the skid tracks on the quayside and begin laying them down.

The topside was skidded over twelve skid tracks, which needed to be perfectly aligned with the skid tracks installed on the barge.

The skidding operation was performed in two stages. First, the topside was skidded five meters to the aft of the barge. Then, after 12 hours to allow for further settling, it was skidded the remaining 130 meters onto the quay, to its final position.

A configuration of 76 skid shoes - divided between the four legs of the platform - and 40 push-pull units were used to skid the topside 15 meters per hour. The combined pushing capacity was 3,320 t, while the total lift capacity was 51,000 t.