Flare gas recovery lies at the heart of a range of integrated, new emissions abatement technologies.

The World Bank’s 2015 launch of the Zero Flaring by 2030 initiative saw flare gas recovery become a standard part of many topside production processing systems. Regulations in places like Brazil, the Gulf of Mexico and the North Sea fortified this voluntary commitment. Now with the industry heading towards zero-emission FPSOs, flare gas recovery is being integrated with more ambitious technology developments.

While field layout and the ability to re-inject or export recovered gas are still major determinants for how much gas is flared, the move towards greater topside energy efficiency, through developments such as electrification, is potentially reducing the other main factor: the use recovered gas for power.

Advances are such that BW Offshore, for example, predicts that the FPSO BW Opal will consume up to 66% less energy than industry standard designs. The FPSO will enter operation next year on Australia’s Barossa gas field, and will include combined cycle gas turbines with waste heat recovery, a closed flame flare system and a hydrocarbon cargo tank blanket system with vapor recovery.

The need for remote operation of equipment is driving developments. MAN Energy Solutions is providing remote process supervision for four HOFIM motor-compressor systems being deployed at the Yggdrasil gas field in Norway. Two of these compressor systems will be installed at the unmanned gas production platform Munin. Head of Sales Upstream Industries, Holger Wörner sees an increasing demand for this small-footprint compressor technology. It is hermetically sealed, oil-free and employs seven-axes active magnetic bearings, so it dispenses with many components typically requiring maintenance in conventional topside compressor systems including gearbox, lubrication-oil system, instrumentation and valving. MAN Energy Solutions is seeing increased demand for its HOFIM compressors.

MAN Energy Solutions is seeing increased demand for its HOFIM compressors.

Image courtesy MAN ES

Virtual sensors allow operators to validate measured data in real time, increasing operational efficiency and accuracy while, leveraging machine learning capabilities, the system also continuously improves performance over time.

Digitalization is also helping optimize the flaring process. With Baker Hughes’ emissions abatement technology, flare.IQ, bp is using critical information from its flare systems, including temperature, pressure, vent gas velocities and gas composition, to help maximize combustion efficiency and minimize emissions. Acting on real-time data from flare.IQ at 65 flares across seven regions, bp can carry out early interventions to reduce emissions.

flare.IQ enables emissions reporting based on real-time measurement in compliance with the UN Environment Program’s Oil & Gas Methane Partnership (OGMP) 2.0 level 4. Growing interest in measurement-based reporting is evident in the growth in OGMP membership which has doubled to over 120 companies since its launch in 2020.

TotalEnergies has used AVEVA’s PI System to create a digital platform that can perform emissions and energy efficiency calculations in real time based on inputs such as fluid composition, process design data and operating parameters. It can now provide real-time calculations of 85% of scope 1 GHG emissions across all of TotalEnergies’ operated E&P assets. It is being used for purge gas optimization, to categorize flaring sources, to detect passing valves and to detect process control anomalies. Demand for decarbonization of FPSO operations is expected to increase rapidly.

Demand for decarbonization of FPSO operations is expected to increase rapidly.

Image courtesy SBM Offshore Image courtesy SBM Offshore

Image courtesy SBM Offshore

Laurent Le Touze, SBM’s Product Development Director, points to the importance of flaring equipment operation. “Amongst the key challenges to be overcome, there are preventing over-pressurization of the flare system and flare gas recovering compressor, preventing oxygen ingress in the gas treatment system and ensuring flaring functions as required, including flare tip ignition.”

Closed flares offer reducing emissions and without visible flame or heat radiation, and the first unit with a closed flare that SBM will operate is the Almirante Tamandaré FPSO in Brazil from 2025. The closed flare gas capacity is calculated based on all continuous very low-pressure gas streams from the produced water treatment and the triethylene glycol (TEG) gas regeneration system. This totals just over 6 million standard cubic feet per day when the compressor dry gas seal system, flare network purge, and some provision for fugitive emissions are also accounted for. The result will be a reduction of about 50kT of CO2 per year or 1,250kT CO2 over the full operating life of the FPSO.

“We observe a dual trend,” says Le Touze. “A push towards reducing emissions driven by international organizations, national regulators, client policies, financial institutions and SBM’s own initiatives, alongside a need for new technologies to emerge. Many technical solutions already exist that could significantly reduce emissions, with the primary one being amine-based carbon capture for which SBM has developed a standard module based on our Fast4ward program. However, these solutions are not always selected by the oil companies due to a lack of CO2 disposal options in the field or because of insufficient incentives to justify the additional investments.”

The Agogo FPSO, designed with a full suite of carbon emission reduction technologies, will be the first FPSO featuring carbon capture technology. Its construction was contracted to Yinson Production by Azule Energy, a 50/50 joint venture between bp and Eni. With an estimated reduction in carbon emissions of 27% compared to a conventional design, the FPSO also includes a closed flare system, hydrocarbon blanketing, combined cycle technology, automated process controls and all electric drive systems. If you can reduce the use of gas turbines on board, you can reduce the amount of overall greenhouse gas emissions, said Lars Tore Haug, Head of Section, Offshore Safety and Systems, DNV. These might account for around 30% of CO2 emissions when, on the more advanced FPSOs, emissions from flaring might be less than 20%.

If you can reduce the use of gas turbines on board, you can reduce the amount of overall greenhouse gas emissions, said Lars Tore Haug, Head of Section, Offshore Safety and Systems, DNV. These might account for around 30% of CO2 emissions when, on the more advanced FPSOs, emissions from flaring might be less than 20%.

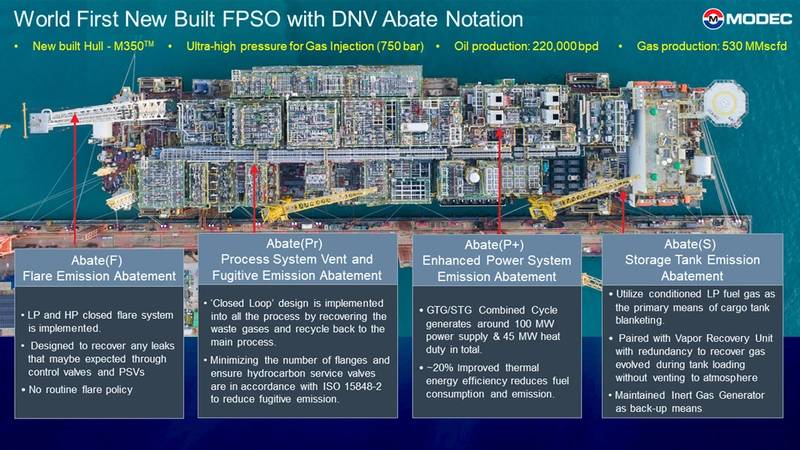

Image courtesy DNV MODEC’s FPSO Bacalhau was the first FPSO to receive Approval in Principle for DNV’s Abate notation.

MODEC’s FPSO Bacalhau was the first FPSO to receive Approval in Principle for DNV’s Abate notation.

Image courtesy MODEC

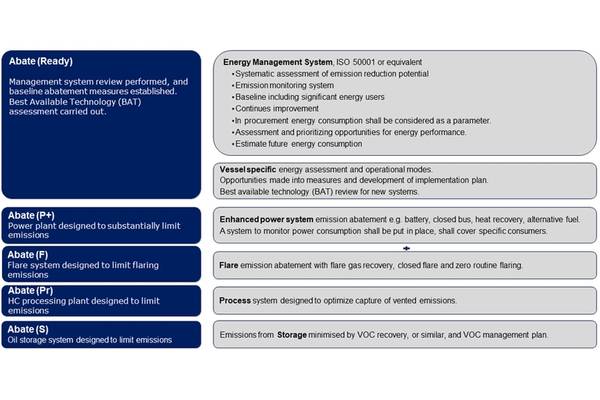

DNV offers its Abate Notation to help assess the viability of the various options available. In July, MODEC’s FPSO Bacalhau, built by Dalian Shipbuilding, was the first FPSO to receive Approval in Principle for the notation. This involves stringent management of emission systems (similar to ISO 50001 Energy Management requirements) and the implementation of substantial abatement measures onboard to prevent non-emergency flaring.

The notation is designed to both nudge the industry forward and to recognize progress already made, says Conn Fagan, Vice President - Business Development at DNV. It provides a structured approach to evaluating the practicality and financial viability of the various options available.

Lars Tore Haug, Head of Section, Offshore Safety and Systems at DNV, says the GHG emissions coming from power generation have become a greater focus than flaring now. “This is one of the reasons why there's a lot of focus on electrification. If you can reduce the use of gas turbines on board, you can reduce the amount of overall greenhouse gas emissions. These might account for around 30% of CO2 emissions when, on the more advanced FPSOs, emissions from flaring might be less than 20%.”

Motivation to adopt new technology continues, most recently in October 2024 with Petronas teaming up with key Asian and international players to launch the ASEAN Energy Sector Methane Leadership Programme 2.0. MLP 2.0 is expected to expedite regional collaboration, facilitating technology demonstrations from partners within and beyond the region.

Image courtesy Petronas